NFC Technology Helps Volvo Penta Secure Engine Testing Process

At the engine testing development department at Volvo Penta, Lundby, quality assurance is high on the list of priorities. The global, world-leading supplier of engines for marine and industrial applications was looking for a solution that could ensure that their engines are tested with the correct fuel quality. The key was to use Near Field Communication technology with CEJN Identification System in combination with 565 series couplings – a unique customer solution.

“If an opportunity arises,

CEJN would be an option in the future too”Stig Lexén

Engine Testing Development, Volvo Penta

Volvo Penta, with about 1600 employees, is part of the Volvo Group. They work with manufacturing and development of heavy-duty diesel engines for both the marine and industrial segments. Simon Anwell is the Manager of Engine Testing Development and he makes sure that the correct equipment is in place in order to determine if the engines pass the qualifications for “Certificate of Production”.

Eliminating potential risks of cross-connection

Eight different fuel qualities are used for different markets and by running fuel tests of prototypes and calculating technical data, they make sure the requirements are reached. Stig Lexén works with Product and Engine Testing Development, responsible for the media pieces, and he saw a potential risk: Fuel hoses could be connected incorrectly, and if the engine would be tested with the incorrect fuel quality this could lead to incorrect emission values which would be picked up during test evaluation in effect making this test cycle corrupt and having to be re-run. Any re-run of testing is costly and can mean delays to engine testing projects. “To ensure we run with correct fuel quality we need to have a system that cross-checks for any errors in selection prior to the start of any test cycles”, Simon Anwell explains.

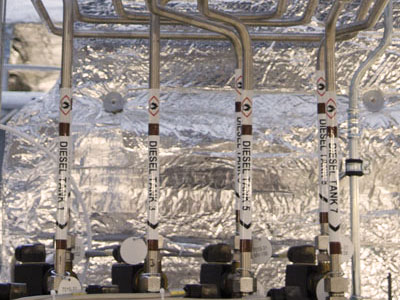

8 different fuel lines coming into the test room could be a potential risk for cross connections.

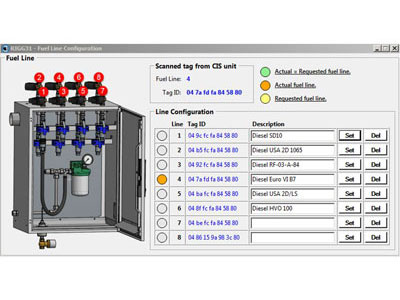

Test cannot be initiated if the connected fuel line doesn't match the expected fuel line.

The coupling has electronic identification of coupling and nipple which makes it possible to verify that the right fuel line is connected.

First prototype within two months

At first, automated solutions seemed to be the way to go to ensure that the right fuel is tested with the right engine, but after careful benchmarking against other test devices, it became clear that engineers need to control the system manually. Different manufacturers were on the table but none seemed to be capable of finding a solution. At an industrial fair in Gothenburg, Volvo Penta – looking for quality, robustness and stability – met with CEJN who took on the task. A week later the CEJN engineering-team investigated the alternatives at the Volvo Penta headquarter. The development procedure was quick and two months later, the first prototype was in place. “To us, it was the software that took the longest time. CEJN had the coupling ready early in the process” Stig Lexén explains.

Electronic identification to ensure poka-yoke

Initially, two sets of the solution were installed into the fuel cabinets to have hardware and software tested. Volvo Penta ended up switching their couplings to CEJN 565 flat-face quick couplings with integrated CEJN Identification System. Each nipple is equipped with a tag with an individual ID. Once the coupling is connected to the nipple, a reader on the coupling reads the ID and the CiS-device sends signals ensuring that the correct engine is connected to the correct fuel quality. If the wrong fuel type is connected, there is a clear indication on the screen and test sequence cannot be initiated –poka-yoke. The solution is a quality improvement: “You can’t run with the wrong fuel now” Simon Anwell adds as he confirms that quality, durability and sustainability are the core values at Volvo Penta.

A simplified testing process

Greatest possible accuracy of measurements is extremely important at Volvo Penta and the new coupling simplifies the engine testing process “We want to keep it simple and remove any risk of human errors” Simon Anwell clarifies. Now that the invention is installed into two of their test cabinets, 11 more cabinets are in production. And as for the future of this project, the cabinets will be equipped with CEJN CiS. Volvo Penta is since earlier a customer of CEJN but mostly within compressed air, and Stig Lexén does not exclude CEJN as a potential partner for upcoming projects: “If an opportunity arises, CEJN would be an option in the future too” and Simon Anwell agrees “They deliver on time, listen and understand our needs” both satisfied with how the cooperation has evolved. It is an exciting project for us at CEJN and it will certainly be interesting to follow how it turns out in the near future.

Do you need a customized quick coupling solution?

500 years of experience are at your disposal. Get in contact with our engineers today for a free requirement assessment.

Engineering Solutions by CEJN

The engineering section of CEJN works with special solutions. Our Application Experts translate customer needs into viable product solutions, while the Design Engineer is the source for custom-made prototypes, small batch runs and special materials. The vision is transformed into a physical product followed by stringent quality testing. We keep a close dialogue with customers and fast processes to meet our customer’s needs.

Related Stories

Swiss chocolate manufacturer chooses CEJN products to meet industry demands

Chocolate manufacturer Max Felchlin AG demands nothing less than high-quality products and top-level customer service from their suppliers to ensure a premium product of the finest chocolate. Along...

Increased performance and no more oil leaks for Reinhard Recycling after installing CEJN TLX

Reinhard Recycling had a problem with oil leaks when disconnecting their couplings from the hydraulic attachments. They were recommended CEJN TLX, a super-duty coupling solution designed to work with...

Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

How much do leakages in the compressed air system actually cost? For the industrial facilities at the Hägglund area owned by NP3 real estate, too much it turned out. After measuring and localizing the...