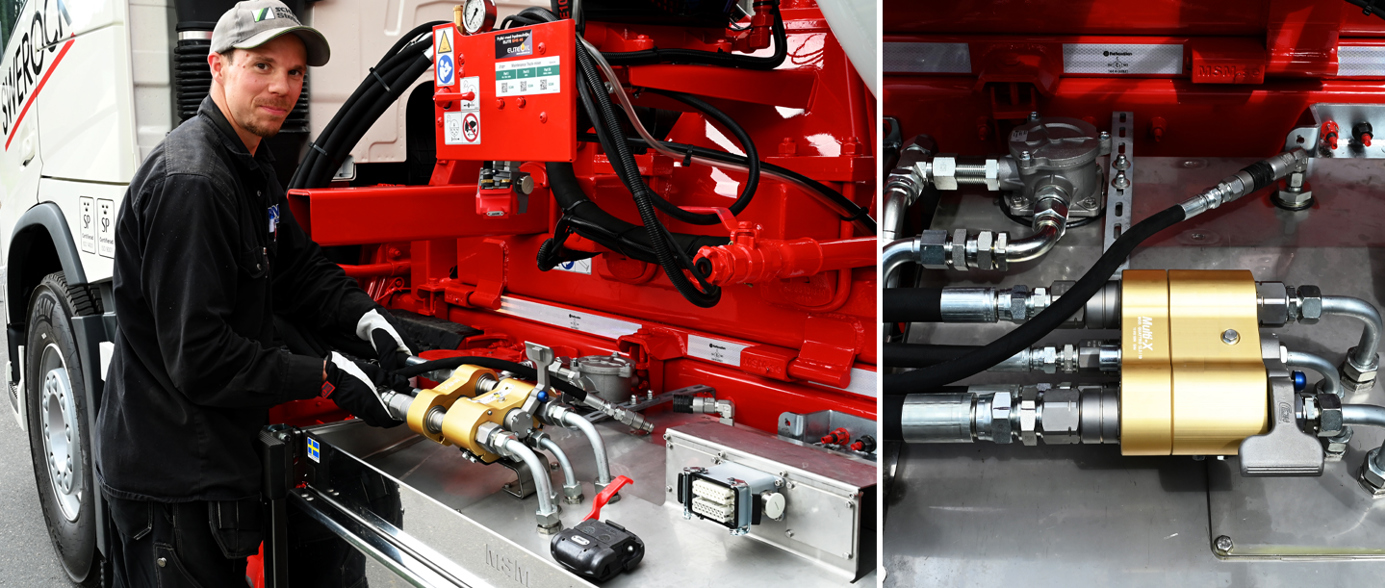

MSM uses CEJN Multi-X GII in their quick-lock truck system enabling a timesaving of up to 6 minutes at each body switching

Time is money. MSM, a Swedish company building truck bodies, uses CEJN Multi-X GII in their quick-lock truck system to fulfill their customer’s requirements of a spill-free, flexible and easy to handle multi-connector – saving up to six minutes at each body switching. “That’s a lot of time-saving every year, a lot of money being saved”, Rikard Alm, production manager at MSM, said.

MSM, Månsarp Svets & Maskin, started as a forging workshop. Now, they are one of Scandinavia’s leading companies building truck bodies. By understanding their customers’ needs and requirements, they can integrate solutions specifically suited for them and their area of business, solutions such as quick-connect multi-connectors.

“Generally, the customer knows what they want, and our job is to meet their requirements and find solutions that will facilitate their everyday work,” Alm said.

CEJN Multi-X is such a solution, meeting the requirements of a spill-free and flexible multi-connector and, most importantly, enabling quicker body switching.

“Using CEJN Multi-X GII, our customers can save up to 6 minutes at each body-switching, resulting in more time on completing the actual job than on maintenance”, Alm points out.

Time is money

The MSM product range covers everything from concrete chutes to hook lift trucks. By implementing their quick-lock system into the vehicle design the truck fleet gets more flexible as it will work for a range of different tasks, i.e., gravel, sand and concrete, etc. The locking system has a failsafe design and includes CEJN Multi-X for easy connections and disconnections of the hydraulics upon each switch.

“A quick-lock system truck means a lot of body-switching on, sometimes, a daily basis, and thereby require reliable and efficient hydraulic multi-connectors to be running smoothly,” Alm points out and continues.

“CEJN Multi-X GII compensates for nine single couplings which, of course, enable not only an easier usage for the operator but also save valuable time at each body-switching.”

Sustainable solution for both users and environment

Compared to if using standard single couplings, the Multi-X can be connected also when there is residual pressure in the system which has been proven to be a true problem solver. This also results in less oil spills during the lifetime of the vehicle thanks to the flat-face quick couplings integrated into the multi-plate design.

“Our customers need to have a sustainability and environmental focus as their customers have environmental demands and requirements on them, such as no oil spill for example”, Alm said.

Usually, the quick-lock system truck is equipped with two multi-connectors. Sometimes, however, they can be equipped with as many as four multi-connectors.

This is Multi-X - advanced technology made easy

CEJN Multi-X is a range of innovative, easy to handle, multi-plates designed to meet the demands of even the most challenging mobile hydraulic applications. It enables to connect multiple hydraulic lines and electrical connectors with just one single connection, even when there is residual pressure and without any risks of cross-connection.

The Multi-X range is an assortment of hydraulic multi-couplings with up to six integrated quick couplings.

MSM AB

Head office: Månsarp, Sweden

Founded: 1968

Number of employees: 26

Industry: Construction industry

Products: Truck bodybuilding

Markets: Scandinavia, Europe, USA and Australia

Website: MSM

Related Stories

Step-by-step guide: How to change the seal on CEJN TLX coupling

Using products that last is a sustainable choice for both the wallet and the planet. Rather than disposing of a product once it reaches the end of its service life, we offer a wide range of spare...

Step-by-step guide: How to install CEJN TLX on hydraulic attachments

In heavy-duty applications, the failure of quick-connect couplings often comes from high surge flows. These surges can lead to seal failures and machine damage, resulting in costly leakages and machine downtime. CEJN TLX is a super-duty coupling solution specifically designed to withstand the...

WEO hydraulic plug-in fittings now available in 5/8”

WEO hydraulic plug-in fittings are known for the versatility and space and time-saving features that also help prevent leakages and premature hose failures. To make WEO available for even more...