Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

How much do leakages in the compressed air system actually cost? For the industrial facilities at the Hägglund area owned by NP3 real estate, too much it turned out. After measuring and localizing the leaks in their 35,000 square metre production area, they replaced all the couplings and hoses with CEJN eSafe and Stream-Line. This switch has saved them over €40,000 a year.

With skyrocketing energy prices due to multiple global reasons, more and more understand the value and importance of having an optimized compressed air system. Magnus Lundberg, Facility and Technical Manager at the Hägglunds area, understood this as early as 2015 when he had LMS Nordic coming to evaluate and detect leaks in their compressed air system. And leaks they found. “By measuring the compressors and the machines, we gathered data showing the operation condition during the evenings, nights, and weekends,” Lundberg says, and continues “We immediately saw that we had many leaks from the couplings and hoses in the system, costing us a lot of money.”

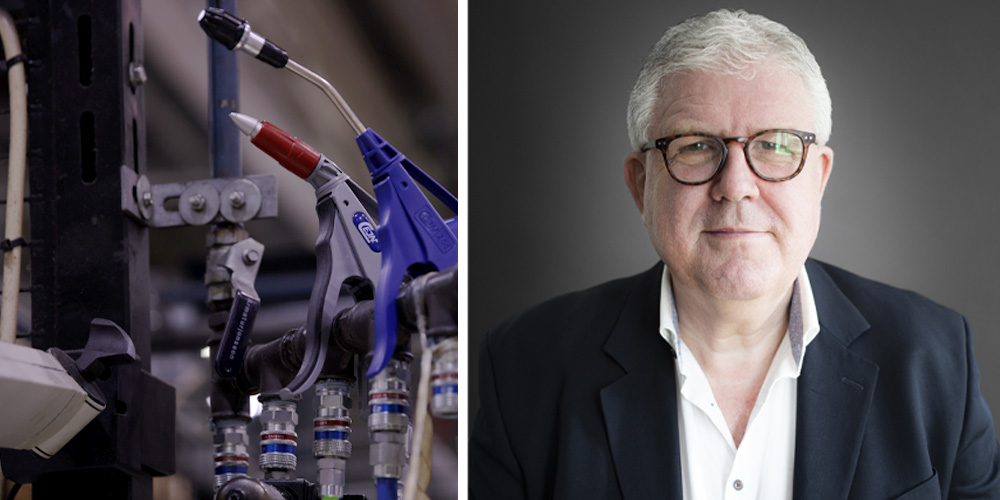

75% of the leakages come solely from supply line components. “Using couplings and hoses of poor quality is a cheap and short-term solution to a bigger problem,” says Daniel Winkler, Senior Adviser and former CEO of LMS Nordic. “Installing high-quality components from the start will save you a lot of money and ensure a safe work environment for the operators,” he adds.

“Installing high-quality components from the start will save you big amounts of money and ensure a safe work environment for the operators.”

- Daniel Winkler, Senior Adviser and former CEO of LMS Nordic

Daniel Winkler at LMS Nordic, to the right, suggested a replacement of current equipment to CEJN eSafe quick connect couplings and Stream-Line hoses after detecting the leaks in the compressed air system.

Surpassed the theory

After detecting the leaks, LMS Nordic suggested a change of all the components to CEJN eSafe quick couplings and Stream-Line hoses. “The knowledge I have about CEJN and their experience in quick coupling technology made the choice of supplier very easy,” Winkler says. “I would never recommend something I don’t believe in myself,” he continued.

“The switch to CEJN exceeded by far the theory as we save over remarkable 520,000 kWh each year”

- Magnus Lundberg, Facility and Technical Manager at the Hägglunds area

The area of Hägglunds invested around €30,000 in replacing all the couplings and hoses to CEJN in their compressed air system. “We saw it as a necessity to do a complete change of the existing equipment to CEJN quick connect couplings and hoses,” Lundberg says. The system covers a 35,000 square metre production area, and in less than a year, the investment paid off.

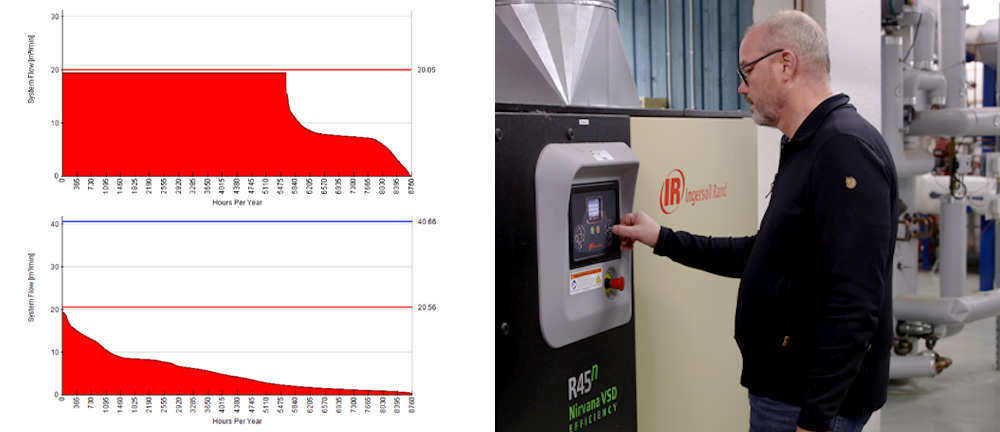

The energy consumption in the facility before the installation of CEJN products was over 814,000 kWh per year. After the installation, that number was down to 288,000 kWh per year. “The switch to CEJN has exceeded all expectations as we save a remarkable 520,000 kWh each year,” Lundberg says. “For us with a cost of €0.08 per kWh, that means over €40,000 in savings each year, and with today’s energy prices, that saving can be doubled,” he concludes. After the installation, they were also able to downsize one of their compressors to half the size.

The measuring results from LMS Nordic of produced compressed air before (top chart) and after (below chart) the installation of CEJN eSafe couplings and hoses.

Better work environment

In addition to the huge savings, the change of couplings and hoses resulted in a safer and more efficient work environment. The eSafe quick coupling is designed with one of the market’s lowest pressure drops and has an inbuilt vented safety function that eliminates dangerous hose-whipping effects. “After the change, overall performance has increased, the operators have safer products to work with and the sound level in the facility has become much lower,” Lundberg says.

The change to CEJN products has resulted in a safer and more efficient work environment for the operators.

A wider issue

Not having an optimized compressed air system is a global issue. Over 30% of all produced compressed air is produced to compensate for all the leakages. That, of course, is not sustainable. According to Winkler, this is due to lack of knowledge. “There is a mindset that if you cannot see the issue, there is no issue,” he says, adding that no one would ever refuel their car knowing that 30% of the fuel was to be spilled, but this is how it looks like in almost 80% of industrial facilities. “We need to continue to spread the knowledge of how much compressed air actually costs and make people understand that this is an easy way to be more sustainable and save a lot of money,” he concludes.

The Hägglund area

Location: Örnsköldsvik, Sweden

Founded: 1899

Number of employees: 1200

Industry: Rental industry for manufacturing and production, offices, data centers and storage.

Website: Lokaler i Örnsköldsvik | Hägglundsområdet (hagglundsomradet.se)

Related Stories

Introducing the 208 Detect blow gun - developed for improved food safety within the food and beverage industry

Within the food and beverage sector, the primary focus remains on upholding the most rigorous standards of food safety. To enhance the safety of the production process, CEJN launches a cutting-edge...

Compressed air optimisation: 5 common leak sources in compressed air systems

Compressed air systems offer a versatile and efficient power source within many industries. High reliability and a favourable cost/performance ratio have kept the compressed air solutions a top...

Introducing the 209 air and fluid guns – designed for workplace ergonomics

CEJN is thrilled to unveil that we now extend our product line for air and fluid guns with a new addition: the 209 air and fluid guns, designed for workplace ergonomics...