Increased efficiency at FMC since Toyota implemented WEO for their forklift trucks

At Toyota Material Handling’s Fleet Management Center called “Truckhuset” (The Forklift Truck House), renovation and maintenance of old forklift trucks are an environmentally conscious and sustainable part of Toyota’s operations. Service at the Fleet Management Center (FMC) is of the highest priority, especially for used forklift trucks. With the WEO Plug-In couplings fitted on Toyota’s forklift trucks, FMC has been able to increase service efficiency, something that is confirmed by the person who most likely has connected more WEO couplings than anyone else ever have...

We are welcomed by Anders Nielsen, Site & Product Manager for Used Trucks at Toyota Material Handling Sweden’s FMC in Mjölby Sweden. He tells us about the history of “Truckhuset” and their journey from vision to a 7000m² re-manufacturing site. They were seeking a sustainable solution to meet a wider range of customer needs with less expensive options, but also make use of the technical longevity of already existing forklift trucks. At the time, plenty of truck parts in good condition could be used for much longer. To change this, they opened Truckhuset.

Re-manufacturing used forklift trucks

To qualify for Toyota’s Approved Used program, trucks are serviced and renovated and if the truck then passes the quality tests, they are ready to enter the market for sale or their short/long term rental programs. Their forklift trucks are always serviced by Toyota.

After an inspiring and impressive chat, we are taken to the workshop where we get to see the actual process. As we walk through the massive area we can spot CEJN WEO couplings and nipples here and there on their Approved Used forklift trucks. Fredrik Grahn, Workshop Technician at Truckhuset, guides us into the technical parts of maintenance. When used forklift trucks arrive at their facility, the ones that are produced in Sweden are already mounted and equipped with CEJN WEO Plug-In hydraulic couplings. Something, that according to Fredrik who renovates 1-2 forklift trucks a week and maintains even more, simplifies a lot. This probably makes Fredrik one of the people in Sweden, and perhaps in the world, who has disconnected and connected most WEO couplings in his life as he is in contact with the truck’s hydraulic systems every week. “WEO is a safe, quality-assured and durable product”, Fredrik says and claims that the implementation of WEO has been tremendously timesaving in his work.

“WEO is a safe, quality assured and durable product”

A timesaving implementation

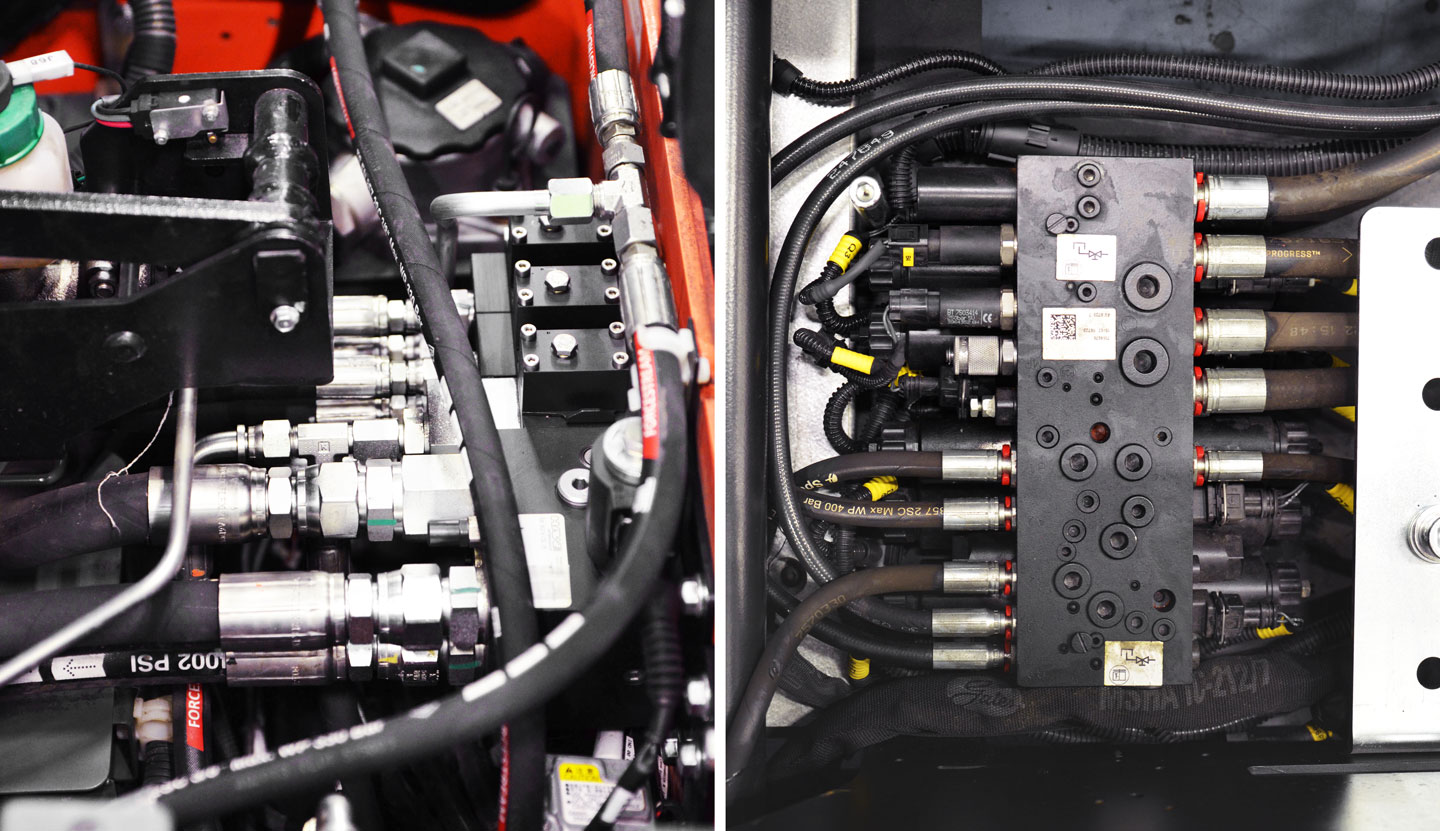

“Comparing WEO Plug-In to screw couplings is like day and night” Fredrik explains as he shows us the complexity of disconnecting screw-couplings. If there is a potential leakage and all couplings have to be disconnected, it takes time to deal with screw-couplings and tools in such a narrow area. There is also a risk of over or under torque when assembling screw couplings. WEO Plug-In is easy to disconnect by removing the assembly stop and is simply connected by pushing in the male nipple. In other words, a quick connection that also avoids leakage.

Fredrik has been there throughout the whole journey of the WEO implementation. He was at first skeptical of the idea but he sure has been convinced. “The hydraulic CEJN couplings are fantastic”, he claims and explains that he has never experienced a faulty WEO coupling, even though they arrive after years of use when he gets his hands on them.

“This is a great example where the customer takes advantage of the benefits with WEO throughout the forklift truck’s entire lifecycle” Pierre Bellehed, Key Account Coordinator, OEM Hydraulics at CEJN AB, points out. From effective and quality assured hydraulic assembly in the factory, to minimal needs of maintenance of the hydraulic connections when in use.

From the left: Screw-connect couplings compared to WEO Plug-In couplings.

Related Stories

Step-by-step guide: How to change the seal on CEJN TLX coupling

Using products that last is a sustainable choice for both the wallet and the planet. Rather than disposing of a product once it reaches the end of its service life, we offer a wide range of spare...

Step-by-step guide: How to install CEJN TLX on hydraulic attachments

In heavy-duty applications, the failure of quick-connect couplings often comes from high surge flows. These surges can lead to seal failures and machine damage, resulting in costly leakages and machine downtime. CEJN TLX is a super-duty coupling solution specifically designed to withstand the...

WEO hydraulic plug-in fittings now available in 5/8”

WEO hydraulic plug-in fittings are known for the versatility and space and time-saving features that also help prevent leakages and premature hose failures. To make WEO available for even more...