Compressed air optimisation: 5 common leak sources in compressed air systems

Compressed air systems offer a versatile and efficient power source within many industries. High reliability and a favourable cost/performance ratio have kept the compressed air solutions a top contender for light and heavy industries even with fierce competition from battery-powered solutions. However, these systems are prone to leaks and require regular maintenance to remain efficient.

Leaks compromise efficiency, increase energy costs and pose safety risks. Leakage control is the quickest way to save energy. The return on that investment can be as fast as 3-6 months. According to the US Department of Energy, a single one-millimetre hole costs the equivalent of €800 every year (https://www.energy.gov/eere/amo/articles/minimize-compressed-air-leaks). When there are leakages, the compressor needs to work harder to provide enough air to the tools, and this is where you start losing money.

An example provided by the US Department of Energy shows that annual cost savings for large industries can potentially surpass €50,000. This calculation is substantiated by a project with the industrial facilities at Hägglunds in Sweden, where annual cost savings have been demonstrated to exceed €40,000.

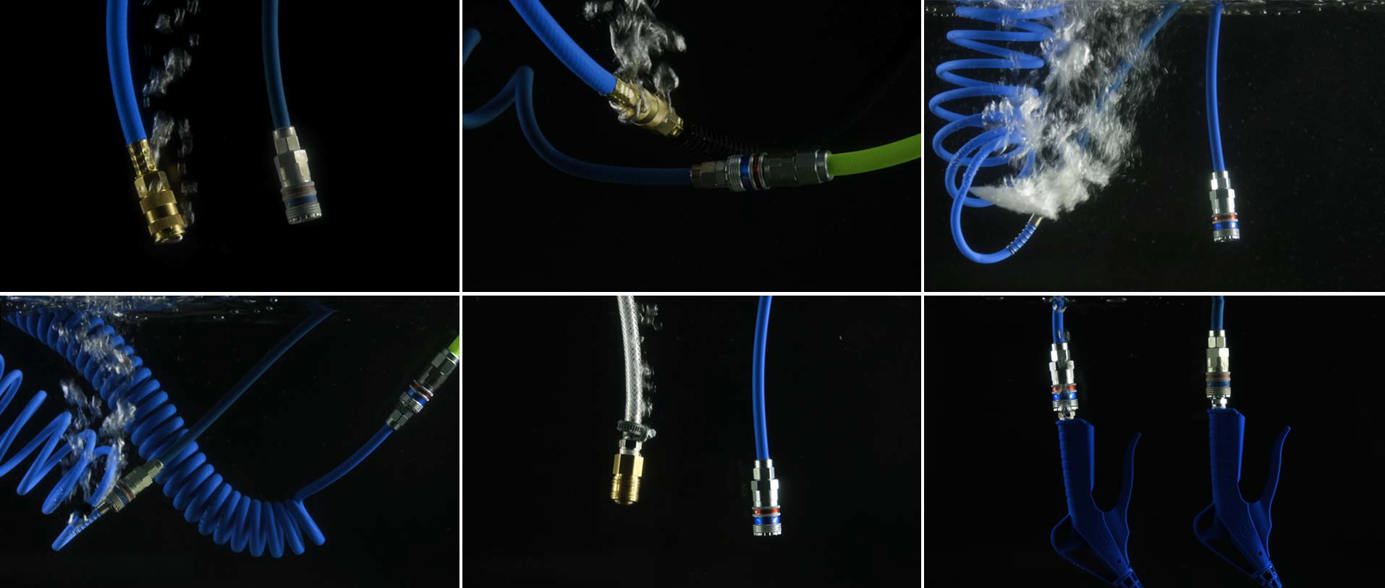

In this article, we explore common sources of leaks in compressed air systems, drawing insightful comparisons with video demonstrations to compare traditional components and their high-quality counterparts.

To start your compressed air optimisation journey, here are five of the most common sources for leaks in compressed air systems:

- Brass couplings and nipples

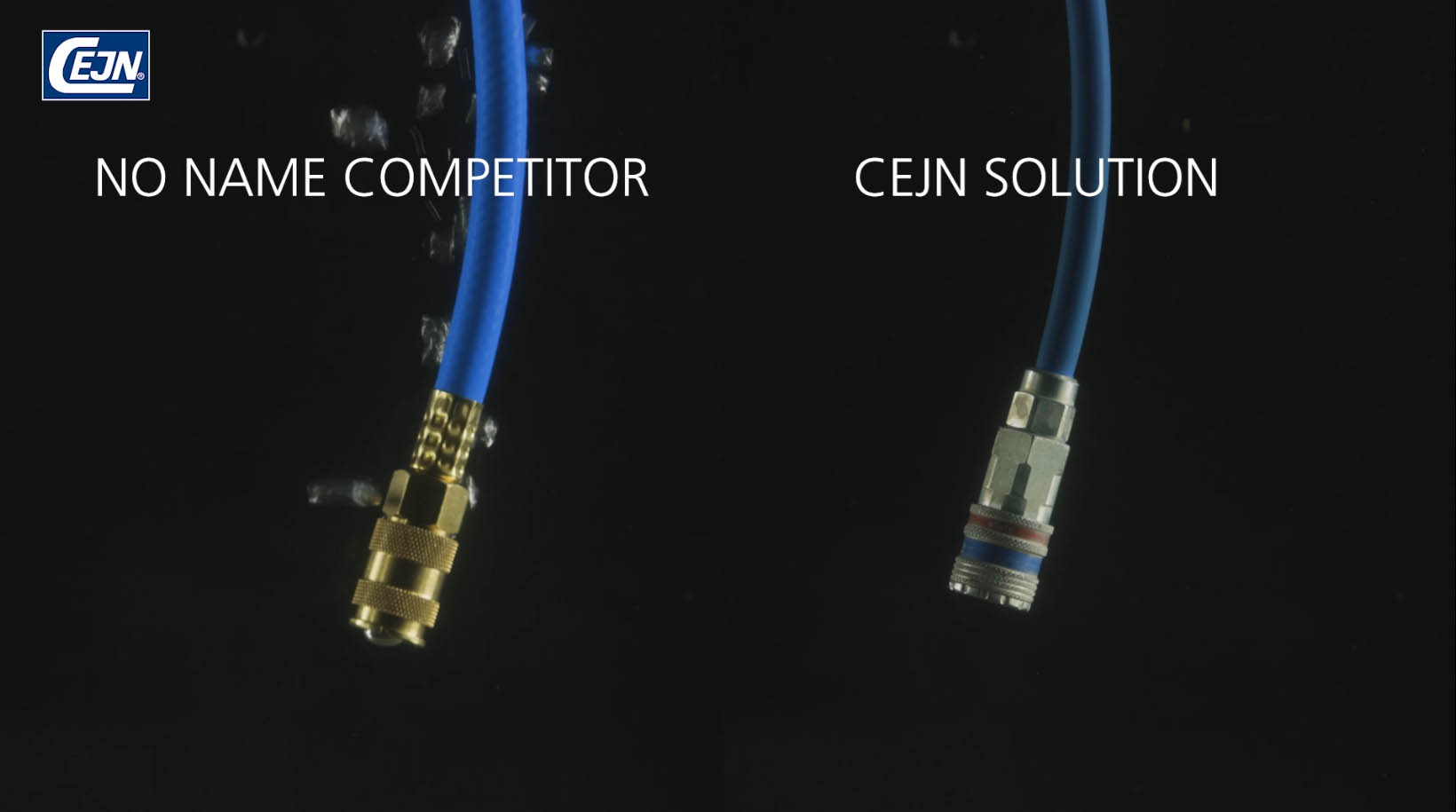

Brass quick couplings and nipples have long been a standard in compressed air systems. Brass, being softer than steel, makes components susceptible to wear over time. Physical damage to nipples and couplings poses a high risk for leaks. Such damage may also lead to the coupling losing torque, a common cause of leaks indirectly related to the softer material.

eSafe quick couplings are constructed from hardened steel or stainless steel to enhance durability against various forms of wear. Additionally, the couplings are adhesive-bonded to the body, providing an extra layer of security to maintain tightness over time.

Investing in high-quality steel couplings and nipples pays off in the long run, reducing the frequency of replacements and maintenance while ensuring energy efficiency.

Also read: Quick connect coupling build materials: Plastics vs Metals

- Low-quality hose material

The choice of hose material is crucial in preventing leaks. Low-quality hoses are prone to abrasion, punctures, and deterioration, resulting in leaks and inefficiencies. Opting for hoses made from high-quality materials enhances flexibility, durability, and resistance to wear. These hoses maintain their integrity under pressure, minimising the risk of leaks.

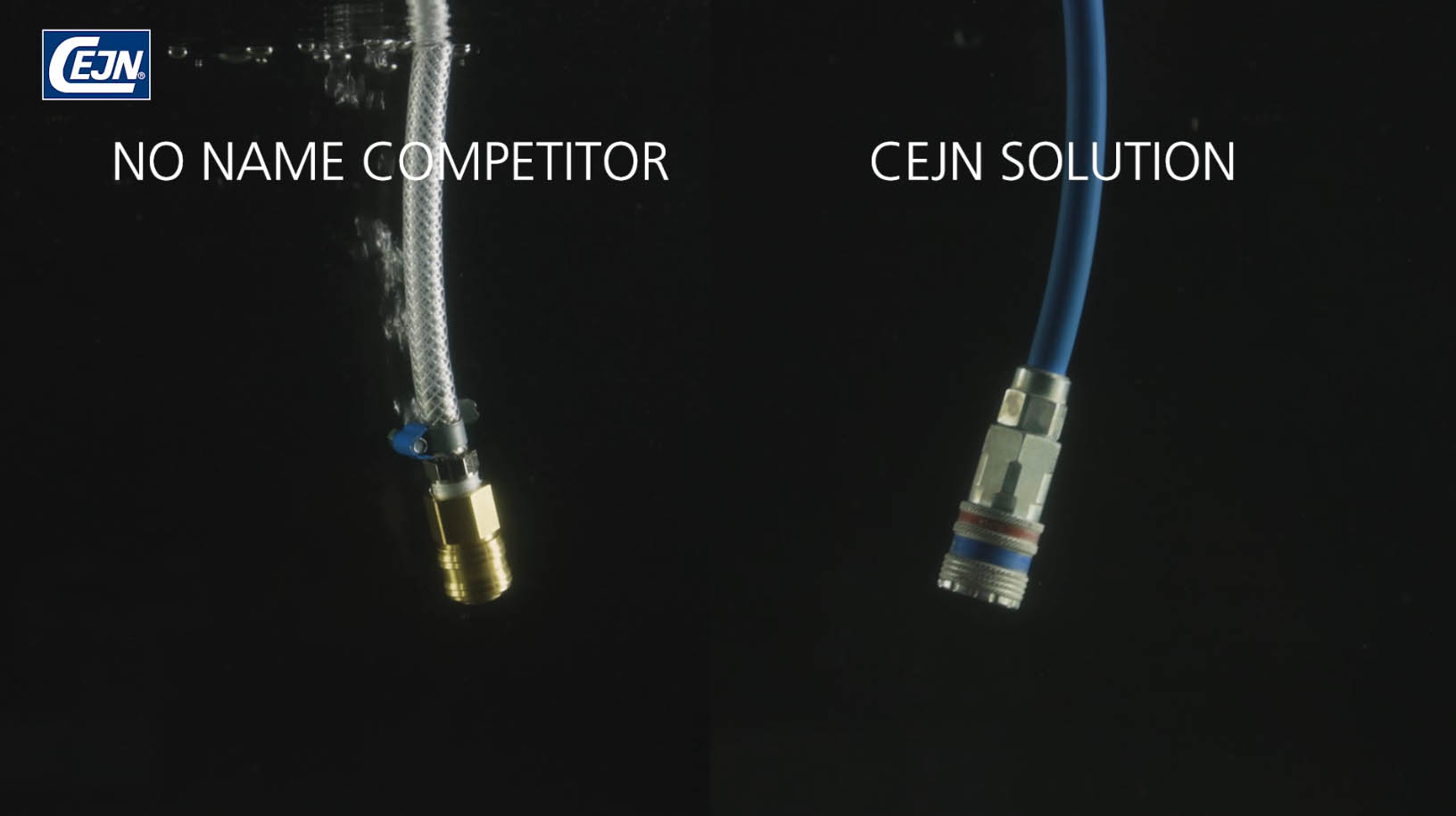

- Leaking hose clamps

Hose clamps are often overlooked culprits in compressed air system leaks, commonly causing leaks at connection points. Higher-quality fittings and quick couplings offer more secure ways to attach them to the hose without relying on the clamp to tighten the connection.

eSafe quick couplings are available with a Stream-Line connection, ensuring a secure attachment to the hose. When a quick coupling is fastened to the hose with the Stream-Line connection, it remains securely attached even under heavy wear. Stream-Line couplings can easily be refitted to the hose in case of damage, offering a convenient maintenance solution.

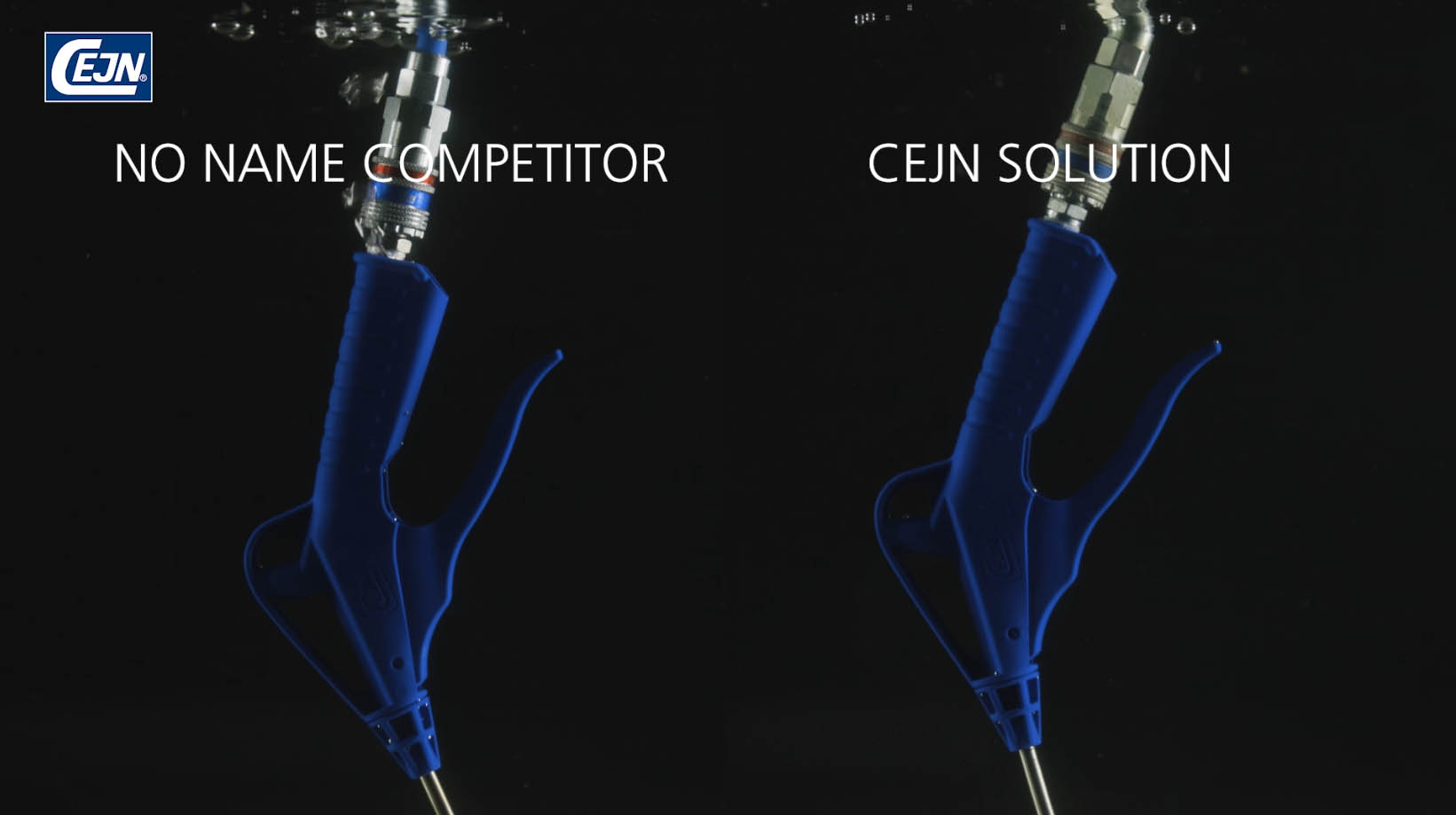

- Poorly executed hose repairs

Quick fixes and makeshift repairs are commonplace in industrial settings but are often insufficient, leading to recurring leaks. Proper hose repair requires using quality materials, correct techniques, and suitable tools. While cutting corners may save time initially, it can easily become a permanent solution, resulting in costly leaks and wasted energy.

Instead of attempting to repair the hose, a more secure solution involves cutting the hose before the leakage point and reattaching the coupling or nipple. This process is significantly simplified using eSafe quick couplings with a Stream-Line connection.

- Poorly sealed nipples

Improper sealing when installing the nipples can lead to leaks. Proper installation techniques are essential for preventing leaks at nipple connections. Choosing a product with pre-installed sealing eliminates the risk of leaks due to improper seals.

Preventing leaks is crucial for maintaining efficiency, reducing energy costs, and ensuring workplace safety. Upgrading traditional components like brass couplings and nipples to high-quality alternatives such as eSafe steel or stainless steel counterparts can significantly enhance system reliability. Additionally, choosing durable hoses and executing proper repairs and installations contribute to a leak-free compressed air system, ultimately benefiting productivity and the bottom line.

More tips for compressed air optimisation are available in the free Compressed Air Optimisation Guide

Related Products

Related Stories

Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

How much do leakages in the compressed air system actually cost? For the industrial facilities at the Hägglund area owned by NP3 real estate, too much it turned out. After measuring and localizing the...

Introducing the 208 Detect blow gun - developed for improved food safety within the food and beverage industry

Within the food and beverage sector, the primary focus remains on upholding the most rigorous standards of food safety. To enhance the safety of the production process, CEJN launches a cutting-edge...

Introducing the 209 air and fluid guns – designed for workplace ergonomics

CEJN is thrilled to unveil that we now extend our product line for air and fluid guns with a new addition: the 209 air and fluid guns, designed for workplace ergonomics...