Great Balls of Steel - An insight to CEJN's work within Ultra High-Pressure

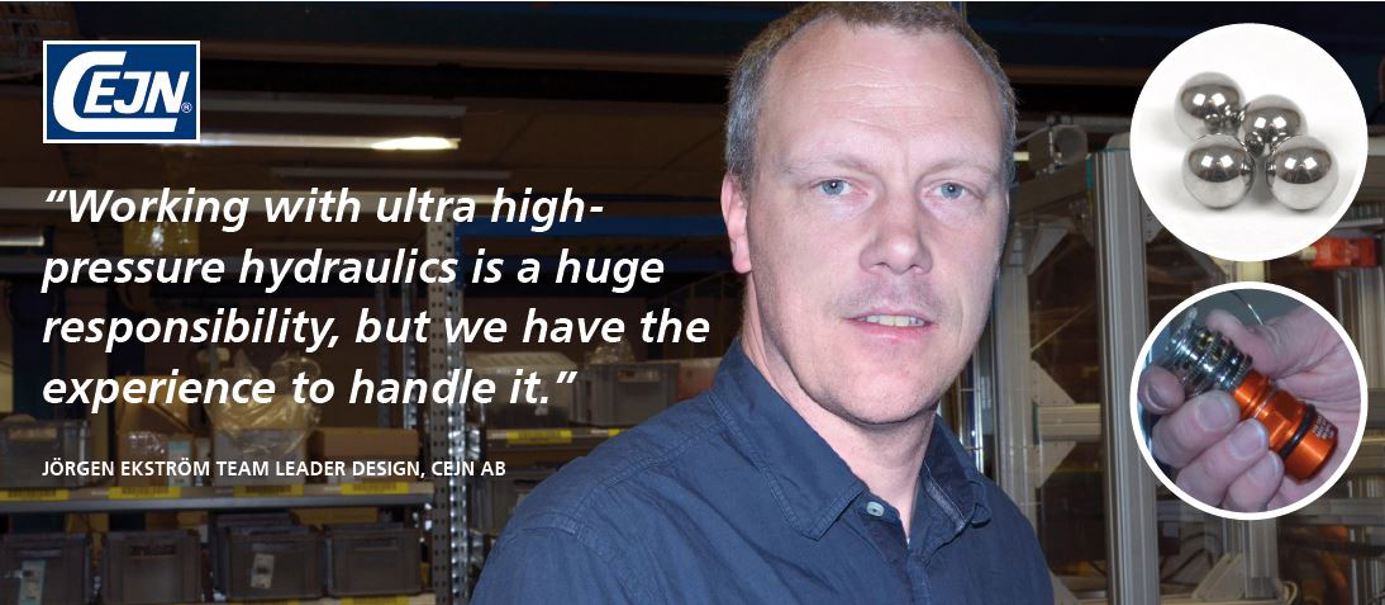

Working with and developing ultra high-pressure products is not for the faint hearted. It´s a meticulous process based on calculations, a variety of test methods and a mind-set based on 40 years of knowledge. At the core of a coupling you find a set of tiny steel balls, carrying a load of approximately 300 kg each. If you can envision an image of two cars (3,000 kg) hanging from a coupling, that will give you an idea of the kind of forces we are dealing with.

The image of the hanging cars representing 3,000 bar is presented by Jörgen Ekström, Team leader in the CEJN AB High-Pressure Hydraulics division in Skövde. “CEJN is a leading player in this segment and we are now developing products for even more powerful applications – 4,000 bar” he explains.

Unique Knowledge

CEJN is a strong organisation when it comes to high pressure products, with 40 years in this particular field. The trend has moved towards higher and higher pressures due to smaller and lighter tools. “These high pressures are extremely challenging, but over the years CEJN has developed an in-depth understanding of how best to maximize the material. We have an understanding of the complicated hardening processes, the right calculation programs and also possess an advanced laboratory where the necessary tests are conducted,” says Jörgen. As there are few appropriate standards for such high pressures, it is up to the company to take responsibility. “That´s why we take this extremely seriously,” says Jörgen.

Only the best is good enough

As quality always comes before price, CEJN only accepts the highest quality from its subcontractors. “As an example, were called and reconstructed a batch of couplings, as our quality tests showed that the steel balls were not good enough,” says Jörgen, proving that cheap will always end up expensive for everybody. Customers of CEJN also demand the best and safest. “The offshore segment is one such segment, and with extreme demands for safety you need to live up to your reputation,” says Jörgen.

Internal safety mind-set

Internally, CEJN goes for 100% functionality tests and pressure-tests all its hose assemblies at its High-pressure centres worldwide.There are a number of functionality tests on the coupling and nipple assembly line, where products are leak-tested and laser-marked in a newrobot cell. “Then there is the laboratory where cycle impulse tests and burst tests are carried out as well as connection and flow capacity tests,” explains Jörgen. The steel balls are one of the parts that require extraordinary quality inspections based on 5 different certificates. CEJN has a lab that very few can match. All hardening methods and finishes are evaluated thoroughly and nousage of chrome 6 is allowed. CEJN also has an organisation adapted to handle problems and customer complaints. “We deal with these kind of problems in a systematic way, with routines and daily Quality Management Board meetings,” says Jörgen.

Developing a customer mind-set

With the new CIS (CEJN identificationsystem), CEJN is taking the safety mind-set one step further. “It is our ambition to help our customers elevate responsibility for safety even more,” says Jörgen. With CIS, CEJN is moving up another rung on the technical ladder, making the technology more intelligent and communication-based. Jörgen says “Our hoses now have traceability and come with a chip system, so customers can see when the hose kit was tested, where it was assembled and when to take it out of service”. As safety is one of the core values at CEJN, the CIS is wholly inline with the ambitions and direction of the company.