Secure your next breath - Requirements for breathing air hoses

When lives depend on the choices you make, making the right one is never more important. Choosing a breathing air hose, intended for its purpose, is essential for you to maintain your workplace safety while working in toxic or unfriendly environments.

Even though a compressed air hose technically can be connected to a breathing air device, it does not mean that it is safe to use due to its purpose. Still, this is quite commonly seen despite the extensive safety requirements of a true breathing air hose. Being aware of the differences between a compressed air hose and a hose intended for breathing air is vital. When referring to compressed air hoses in this regard, we mean compressed air hoses that mainly are intended for the air supply of pneumatic tools.

Maintain your workplace safety

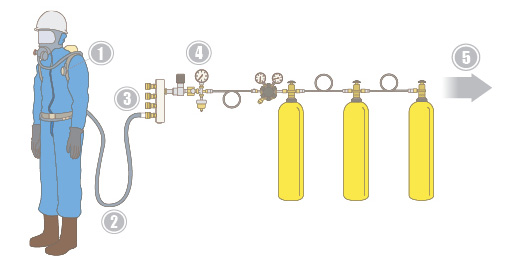

When choosing hoses for your breathing air devices, make sure they meet and exceed the safety standards, and adhere to these five steps of breathing air safety in your system:

- Alarm indicating leakage

- High quality breathing air hose kits following breathing air standards

- High quality breathing air quick connect couplings

- Regulator adapting air pressure to 2 bars for your lungs

- High-pressure thermoplastic hose kit between compressor and cascade bottle system

Requirements for breathing air hoses

For a breathing air hose to be classified as such, it needs to meet the requirements according to the European standard of ‘REGULATION (EU) 2016/425 - personal protective equipment’ which include the following standards:

- SS-EN 14594: Respiratory protective devices - Continuous flow compressed air line breathing devices - Requirements, testing and marking.

- SS-EN 14593-1: Respiratory protective devices - Compressed air line breathing devices with demand valve - Part 1: Devices with a full face mask - Requirements, testing and marking.

Stringent testing according to European standard

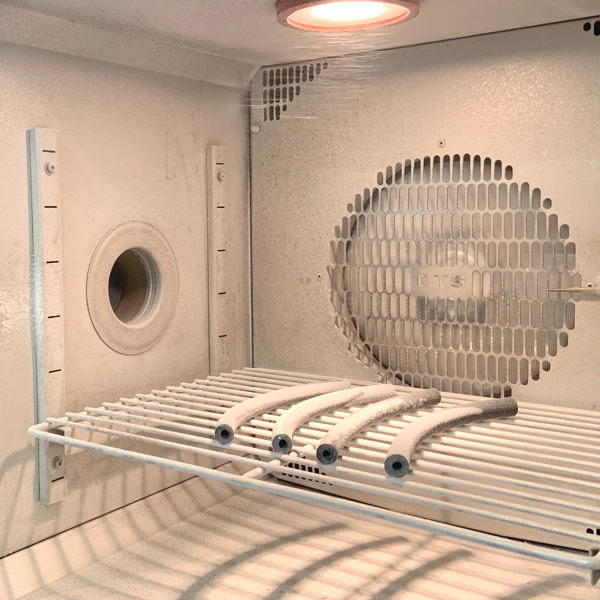

At CEJN, our breathing air hose kits go through several tests to ensure proper assembly and premium performance. Before any tests are run, the hoses are subjected to conditioning which means they will be tested in different types of climate environments to measure and ensure their strength in extreme temperatures.

Once the conditioning test is completed, the coupling, as well as the hose, goes through a burst pressure test, tensile test and flexibility test.

A breathing air hose is made to withstand a tensile test of 102 kilos (1 000 N) for five minutes, while a compressed air hose only can withstand around 50 kilos (500 N), i.e. about half against a breathing air hose. So even if it is possible to connect a compressed air hose into your breathing air device, it is not as safe as using the right equipment. A breathing air hose is also much more heat resistant and durable than a compressed air hose.

Conditioning tests will put the hose through extreme temperatures.

A breathing air hose should withstand a 5-minute tensile test of 1000N.

Taking safety to the next level

To guarantee the correct assembly, a small inspection hole has been incorporated in the ferrule. During the quality control, we can easily check and make sure that the hose, during the crimping process, was properly installed. You can, at any time, e.g. if your hose kit has been subjected to heavy loads, glance at the inspection hole to make sure your hose is still in safe working order.

CEJN offers three different kinds of hoses, each of which is suitable for different application areas and assembled to your specifications. Choose the hose that fulfills your requirements and we’ll cut it to your preferred length and, depending on your specifications, assemble our high-performance, quick connect coupling and nipple when required.

Read more about our Breathing Air offer >

Did you know...

…that CEJN has introduced green marking on all standard breathing air series: 341, 342 and 345. By adding color-coding to Breathing Air we make it easier and safer to connect when you have various connectors - like compressed air and breathing air in your workshop. Did you also know that it's mechanically impossible to cross-connect a Breathing Air series 341, 342, 345 with an eSafe Compressed Air and vice versa?

Related Stories

Introducing bSafe - Breathing air hose reels

We are now extending the popular Safety Reels with a hose reel fitted with hoses intended for breathing air. The features of the Safety Reels combined with the safe and tested breathing air hoses are...

FAQ - common questions and answers about safety reels

Here we have gathered some common questions and answers about our safety reels...

The strategic purchaser’s requirements on CEJN - quality and lead time

Sundström Safety is a manufacturer of high-quality respirators. Their highest rated products are fitted with hoses and compressed air couplings from CEJN. A collaboration that has now been running for...