FAQ - common questions and answers about safety reels

1. How do I adjust the spring tension on my hose reel?

To adjust the spring tension, watch the instruction movie.

2. Can the locking mechanism be deactivated?

To deactivate the locking mechanism, watch the instruction movie.

3. Can the position of the stop ball be adjusted?

Yes. Watch the instruction video.

4. How do I safely change the hose on my reel?

To safely change the hose on your reel, watch the instruction movie.

5. My reels re-winds too fast, what can I do to prevent that?

If the reel has stopped braking and the speed of the hose re-winding is significantly higher than before, you can replace the worn out brake shoe with new ones. To do this, you need will need some tools and mechanical "know-how". If you don't feel comfortable doing this, contact your local dealer for help. If you want to replace the brake shoe yourself, watch the instruction video.

6. Why does my reel not re-wind the hose?

Sometimes, when repeatedly only using just the first portion of the hose length, the hose gets tangled up inside the reel. To prevent this, just un‐wind the hose completely and let it re‐wind without assistance so that the hose guide system can work. If you still have problems with the hose not re‐winding properly, please contact your local dealer for support.

7. What is the maximum height at which a reel can be mounted?

The maximum height at which a reel can be mounted is limited by spring force and hose weight including media. We don't recommend you mount a reel higher than 13' from the floor.

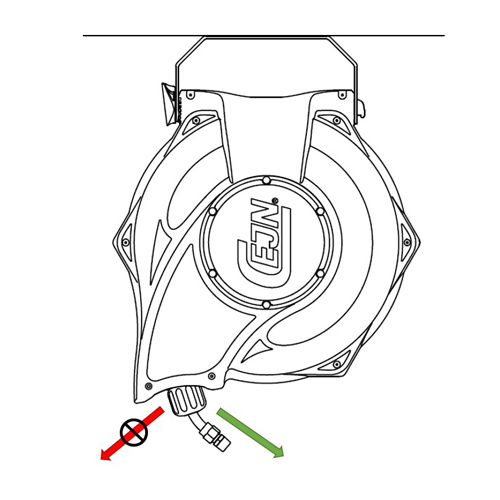

8. Can the reel be mounted into the ceiling?

Yes. When mounting the reel into the ceiling, choose a position so that the hose runs out of the opening towards the "bottom" of the reel (see picture). This will facilitate the operation of the reel.

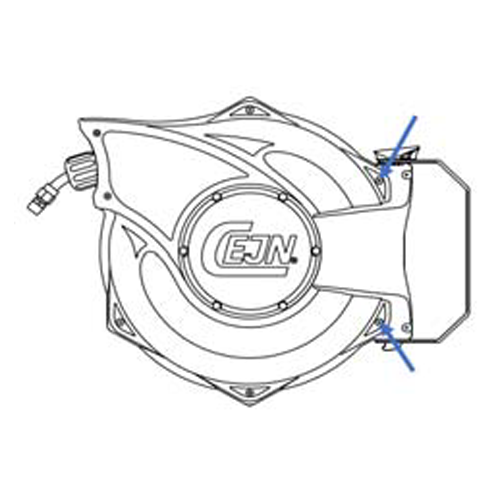

9. Do I need to secure the reel further when mounting it into the ceiling?

This is not necessary, the standard bracket and locking mechanism hold for around 100kg pull force. However, if extra safety is needed, a thin wire can be attached to one or both of the rear cover holes (see picture). To perform this operation, you may have to drill holes in the positions shown.

10. Does the reel work with negative pressure?

Yes. The reel and braided PUR hose can be used up to 90 percent vacuum.

11. What chemicals are compatible with my reel?

Review the Chemical Compatibility Guide for PUR (ether/ester), POM, PP, NBR and brass to find out which chemicals that are compatible with your reel.

12. What do I do if the packaging is damaged when arriving?

If the box is damaged on arrival, please contact the responsible logistic partner and examine the reel for damages. The packaging has been tested according to ISTA regulations and transportation damage should therefore first be claimed to your logistic partner.

13. Can the reel be used for breathing air applications?

If you order a reel from the model program that is prepared with breathing air approved grease, it is possible to use for breathing air applications. Do not use standard pneumatic reels for breathing air applications. You can read more about breathing air safety and requirements here.

14. Is it possible to get the reel and/or hose in a different color?

Yes it is possible to have the covers and/or the hose in a different color. Contact your local sales representative in your region for quotation. Note: stop ball and cable reel is not possible to get in other colors.

17. Can I use water in an air-reel?

No, we don't recommend that as water in a pneumatic hose might disintegrate the hose over time resulting in leakage.

18. What pull force can the bracket withstand?

The standard bracket withstands around 100 kg pull force.

19. Can I repair the reel myself if it breaks?

Yes. We have spare parts or spare kits for the majority of the reel components. You can read more about it in our manual for hose & cable safety reels (closed) here.

Related Stories

Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

How much do leakages in the compressed air system actually cost? For the industrial facilities at the Hägglund area owned by NP3 real estate, too much it turned out. After measuring and localizing the...

Compressed air optimisation: 5 common leak sources in compressed air systems

Compressed air systems offer a versatile and efficient power source within many industries. High reliability and a favourable cost/performance ratio have kept the compressed air solutions a top...

Now available! The 209 air and fluid guns – designed for workplace ergonomics

CEJN is thrilled to unveil that, within short, we have extended our product line for air and fluid guns with a new addition: the 209 air and fluid guns, designed for workplace ergonomics...