Quick coupling solutions for Wind

Safe and reliable quick coupling solutions facilitate both the manufacturing, installation, maintenance and operation of wind turbines. High-pressure couplings are ideal for secure bolting and non-drip couplings will help to provide an efficient liquid cooling solution.

This is how quick couplings help improve wind turbine maintenance, operation and manufacturing

- Efficient and safe bolting with ultra high-pressure hydraulic quick couplings

- Non-drip liquid cooling quick couplings enable pre-filled parts to help reduce onsite maintenance and production down-time

- Efficient manufacturing using compressed air tools and high-flow safety couplings

Ultra High-Pressure Bolting Solutions

Wind turbines are subject to extreme conditions and vibrations. Large wind turbine installations consist of more than 20.000 bolts that need to be exactly tightened using hydraulic bolt tensioning tools to reach specified bolt loads. Safe bolting, whether it is on land or offshore, using CEJN quick connect couplings to power hydraulic bolt tensioners, makes the job quick and efficient.

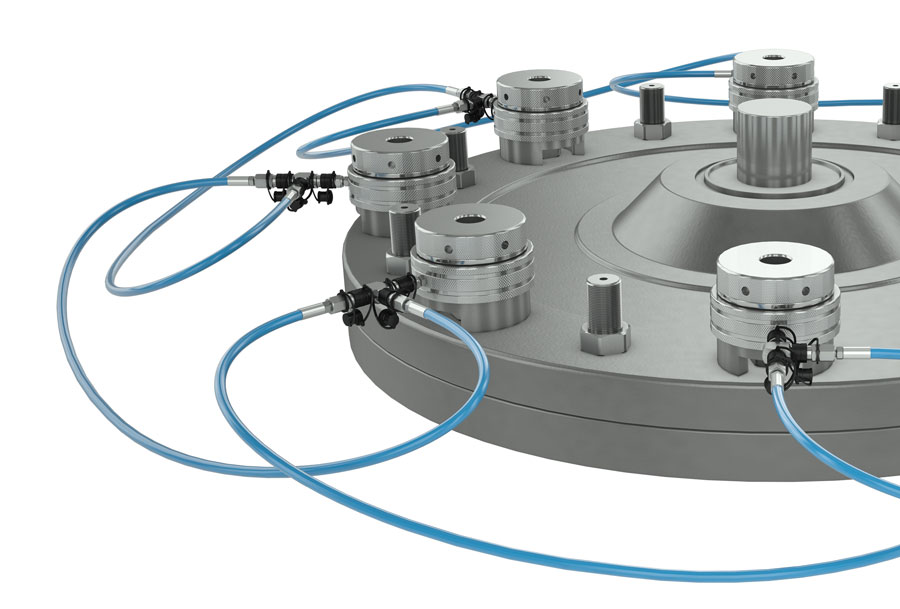

1. The wind turbine needs to be securely bolted to the foundation with an exact torque. CEJN ultra high-pressure quick couplings together with high-pressure T-connections are used to simplify simultaneous connections for hydraulic bolt tensioners.

2. Rising more than 150 meters above ground, the tower needs to be bolted and also for bolting the nacelle frame, gearbox, yaw bearing and main bearings. CEJN quick couplings offer safe and reliable power for pressures up to 4000 bar.

3. The shaft is attached to the hub and the blades are bolted in place. The confined space could potentially put the technician at risk. CEJN quick couplings are safe and durable. They are also equipped with unique safety features to protect against accidental disconnections.

4. Regular maintenance is required and all of the bolts that keep the installation securely in place needs to be re-bolted on a regular basis. Quick and reliable tools are required to minimize downtime and production loss.

CEJN Identification System (CiS)

CiS is a tracking solution in which every hose kit is chipped and has an individual marking and traceability based on Near Field Communication technology. This means that you can check the technical data for the hose kit and can also view an updated history log: when the hose kit was first and most recently pressure-tested and when it is time to take it out of service.

Safety lock secures the connection

A quick and smooth locking ring gives extended security to your connection. Screw locks are sometimes considered by users to be time-consuming and left unscrewed. With the safety lock on the ultra high-pressure quick couplings, unintentional disconnection is practically eliminated, just a quick twist of the bayonet lock and your hydraulic coupling is secured.

T-connections simplify simultaneous connections

T-connections help simultaneous connections for bolting using single port bolt tensioners. Old porting block solutions can be replaced with a single, leak tested and ready-to-use component minimizing the risks of leakage.

It is compact and, thanks to a modified seal, the valve in the nipple can handle dynamic load while disconnected without the risk of seal damage. This means that it is safe to have a disconnected nipple at the end of a serial connection and there is no need for plugged couplings.

"We use high-quality products, so the service technicians can do their job more efficient and in a safe way"

Cecilia Dalmyr, QHSE Manager, Connected Wind

Recommended products for ultra high-pressure bolting

Quick couplings for liquid cooling maximizes power generation

Time and money-saving benefits of quick couplings in the liquid cooling system of wind turbines:

- Pre-filled liquid cooling manifolds for quicker on-site maintenance and increased production up-time

- Vibration resistance to secure the cooling circuit during long periods of operation.

- High-efficiency quick couplings with low pressure drop for a more efficient cooling system that requires a lower pump pressure

Save money on maintenance with pre-filled cooling modules

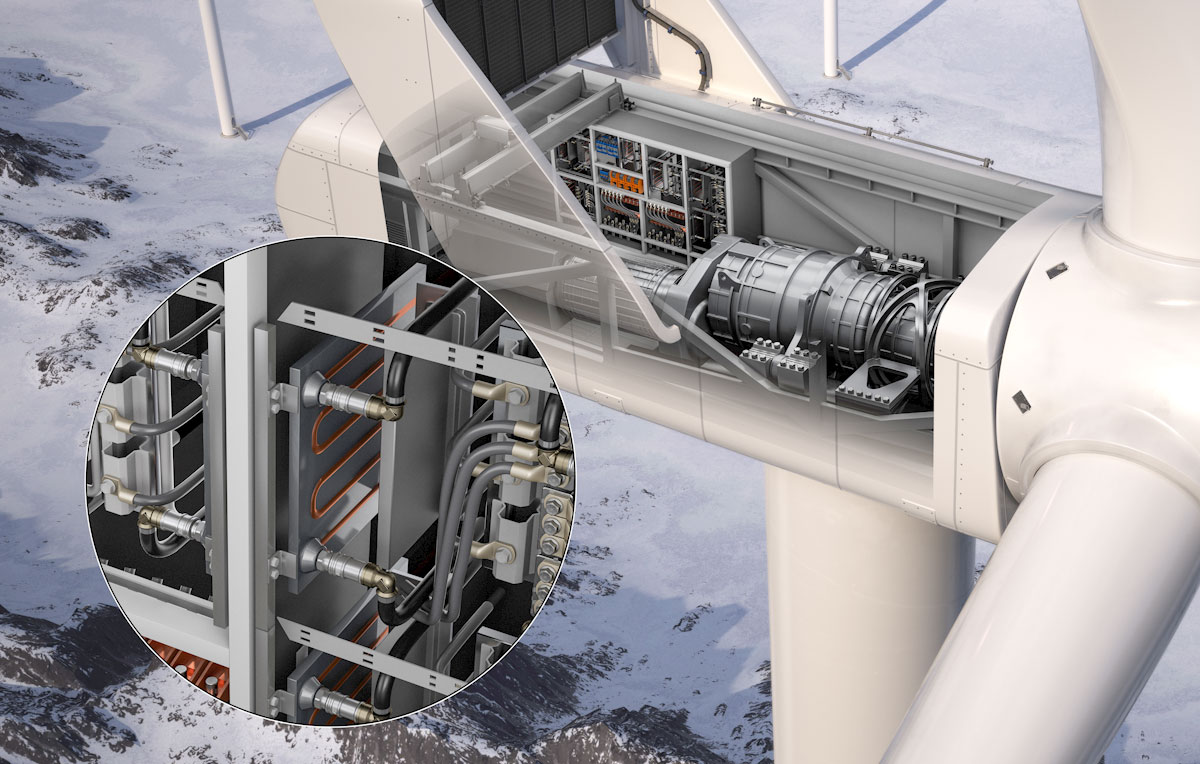

With wind turbines getting bigger to increase power output, the amount of heat generated from frequency converters and electronic control systems have passed the border of what conventional air cooling can manage. For the largest wind turbines, liquid cooling is necessary to keep the electronics in safe and operational temperature.

Using quick couplings, service technicians can work with pre-filled cold plates and just exchange them on the field to minimize turbine downtime and do the maintenance off-field while the turbine is producing.

Did you know that…

- Power electronic transistors are shown to be one of the most failing parts in the wind power turbine due to the failure of successfully dissipating the heat?

- The consequences can lead to a standstill, revenue losses, and system failure?

- The maintenance costs of a failing power electronic transistor can go up to €100.000 per day?

Quick Connect Couplings:

A Critical Component in Liquid Thermal Management Solutions

Recommended products for liquid cooling of converters

Compressed air for wind turbine blade manufacturing

Wind power manufacturing requires high efficiency compressed air tools for grinding, cutting, sanding and polishing. The easy interchangeability and the high power output of tools in a compressed air system makes it ideal for wind power manufacturing. Tool efficiency depends on the airflow and anything that limits the airflow will lower the overall tool performance. Optimizing the compressed air system by spotting and tightening existing leaks and change old couplings to modern high-flow safety couplings will have the potential to increase both productivity and performance.

Quick coupling solutions to increase manufacturing efficiency and safety

- High performance quick couplings increase performance and safety

- Safety tested and quality approved hoses and quick couplings for breathing air

- Safety hose reels with high visibility hose to avoid tripping accidents

- OSHA approved compressed air blowguns

Optimize the performance of your compressed air system with eSafe safety couplings

- More power to your tools with high-flow quick couplings

- Low-noise connection and disconnection without recoil

- Tested for durability and performance after many years of use

Up to 69% higher efficiency with eSafe safety couplings

Recommended products for maintenance and manufacturing

Related Stories

CEJN proud member of GWEC and their work for more sustainable energy solutions

One thing is clear. More sustainable energy solutions are needed to fight climate change. CEJN stands behind the work of enabling more energy using wind power and is a proud member of the Global Wind Energy Council (GWEC...

How quick connect couplings reduce wind turbine maintenance costs and help to prevent IGBT failures

Power-electronic converters in wind power turbines are critical components. They are shown to be one of the most frequently failing parts, according to an article from MDPI (source: MDPI). The most...

New safety feature improves safety and efficiency of high pressure couplings

Connected Wind on the importance of safety when working with high pressure hydraulics: "The new locking feature makes me feel much safer. It lets me focus on my job instead of worrying about the tools I'm using...