Energy efficient solutions for the manufacturing industry

Costly compressed air systems are a global issue. So how come that in 80% of industry manufactories', this is the case? The short answer is lack of knowledge. With poor couplings and hoses, leakages will occur. Over 30% of all compressed air is produced just to compensate for all the leakages. Not very sustainable or economical. Looking over the system and replacing poor-quality supply line components with high quality quick connectors and hoses will save a lot of money, improve the tool performance, and have a positive impact on the environment.

Small changes, big impact

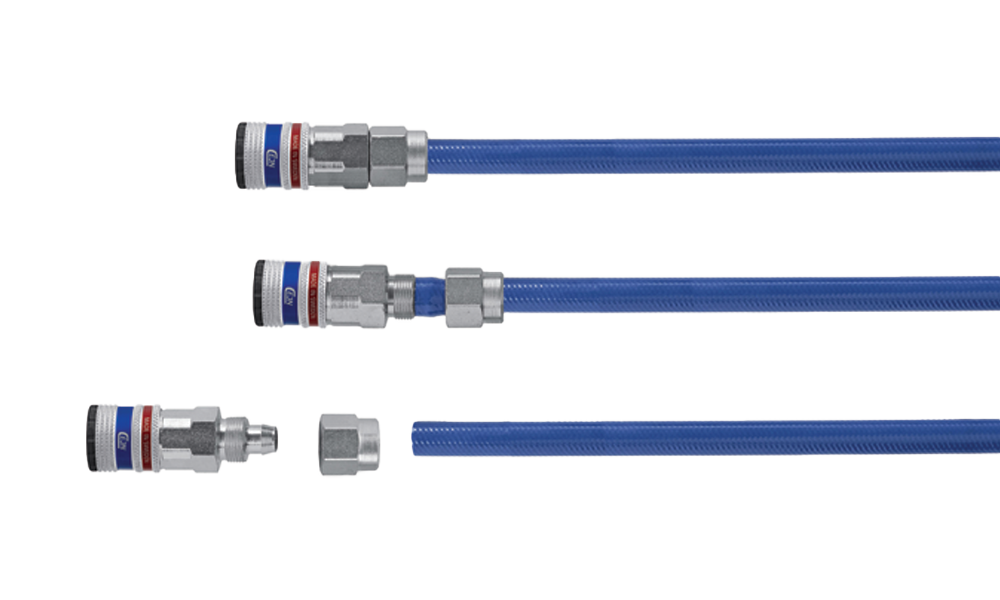

Looking over the compressed air system and replacing poor-quality hoses and couplings will increase the tool's performance and decrease the energy bill and the environmental impact. The CEJN eSafe quick connect couplings have the highest flow on the market and that, combined with a low pressure drop, makes it a reliable product for years to come.

Common assumptions using compressed air:

![]()

"Air is free"

One of the most common misunderstandings is that air is free. It is definitely not. Leaking hoses and poor compressed air equipment actually costs a lot of money, even though it is not shown on the energy bill.

![]()

"The tools work just fine"

The tools might work, but do they work at their full capacity? You can still water plants with a leaking hose, but it will be highly ineffective and you will spill a lot of water. The same scenario applies to tools using compressed air; they might work, but not optimal, and a lot of air (money) is wasted.

![]()

"Manufacturing industries always have a high sound level"

Well, it does not have to be. A leaking hose generates a hissing sound, imagine then the sound from maybe a hundred or thousands of leaking hoses, every minute of every day. Ensuring no leaks in the compressed air system will reduce the sound level significantly.

What do our customers say?

Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

“The switch to CEJN exceeded by far the theory as we save over remarkable 520,000 kWh each year”

- Magnus Lundberg, Facility and Technical Manager at the Hägglunds area.

Volvo improves their compressed air system with CEJN eSafe

“As we immediately saw savings with eSafe due to less pressure on the compressors, we have continued the optimization process with hoses and reels from CEJN”

- Benny Reinhardt, Maintenance Technician at Volvo

Midroc Electro AB about the importance of having the right products in the right places for an optimized system

Many people get what they think is a cheaper product, but what they do not know is that the air runs right through it.

- Reino Hedman, General Manager at Midroc Electro AB

No more issues with bad hose clamps using CEJN Stream-Line

CEJN Stream-Line is an extended version of eSafe quick connect couplings containing reusable nipples and connectors. Using Stream-Line fittings with your PUR hose, your hose can be as good as new in a couple of seconds, maintaining clean hoses in the production environment. In an easy maneuver and with few tools needed, the fittings can be removed from the current hose and attached to a new one. Simple as that.

Next-level workplace safety with CEJN hose reels

Efficient and durable compressed air reels increase workplace safety with automatic hose retraction to keep hoses off the floor to avoid potential tripping hazards. Unrestricted airflow saves energy and improves tool performance. The hose reels are designed for professional use with high-quality components for long expected service life. Multiple installation options and swing brackets help create an ergonomic workplace where the compressed air power source is always available.

Related Stories

Compressed air optimisation: 5 common leak sources in compressed air systems

Compressed air systems offer a versatile and efficient power source within many industries. High reliability and a favourable cost/performance ratio have kept the compressed air solutions a top...

Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

How much do leakages in the compressed air system actually cost? For the industrial facilities at the Hägglund area owned by NP3 real estate, too much it turned out. After measuring and localizing the...

NFC Technology Helps Volvo Penta Secure Engine Testing Process

At the engine testing development department at Volvo Penta, Lundby, quality assurance is high on the list of priorities. The global, world-leading supplier of engines for marine and industrial...

Guide to Quick Couplings for Production Test Applications

Testing should be a natural part of all product manufacturing to secure product quality and to quantify technical data for documentation. Inaccurate tests are costly both in terms of testing costs, possible penalties for inaccurate specifications but also for the delayed time-to-market. Here are the...

CEJN eSafe ensures student safety

The Volvo High School at Volvo Cars Engine has one of Sweden’s highest application rates and the few lucky students who are accepted are highly prioritized by Volvo. I meet with Marcus Jerne, a teacher at the school, to discuss their switch to our compressed air coupling eSafe...

Energy Efficiency Gains Top Focus

Brammer UK & CEJN UK meet industry challenge by strategic partnership Todays competition within the industry is more challenging than ever. New regulations for energy efficiency, such as the Energy...