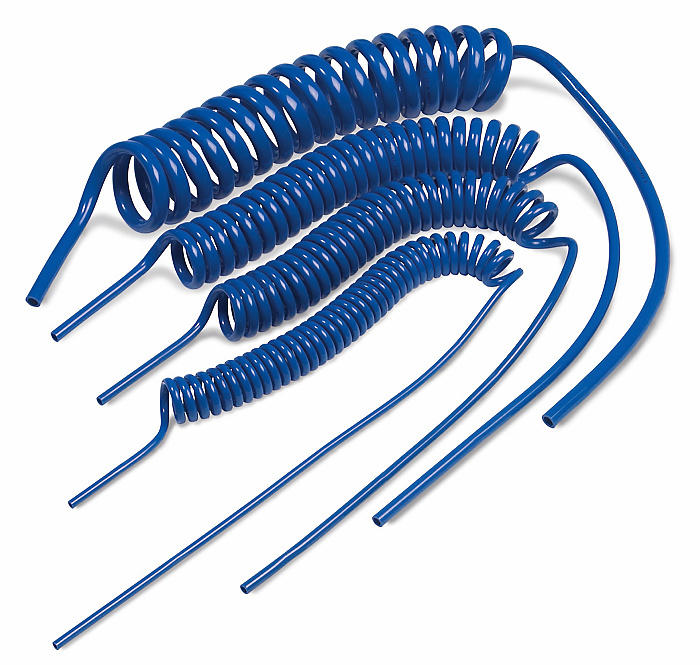

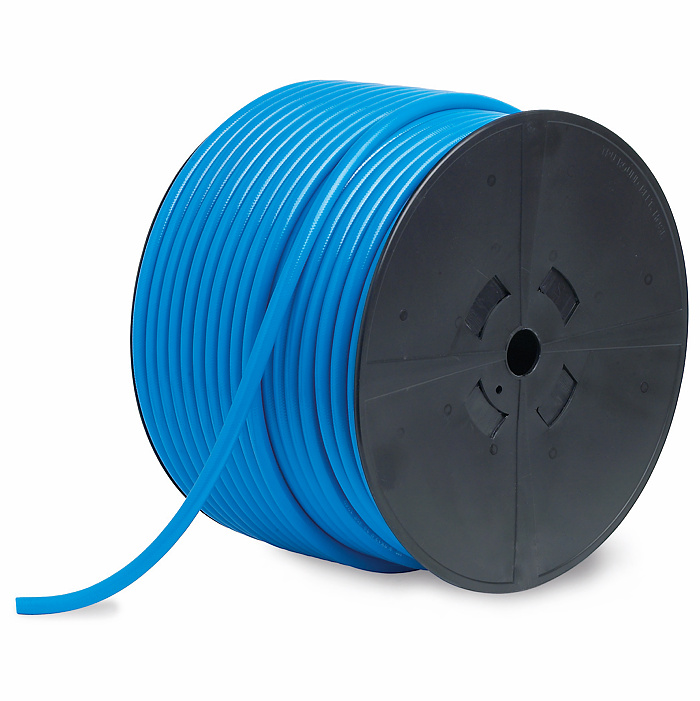

Compressed air hoses

High-vis Anti-spark Antistatic Stream-line

Straight/spiral braided and non-braided polyurethane (PUR) or rubber (EPDM) hoses for compressed air are light and flexible and offer long service life and outstanding aging qualities. They provide excellent resistance to oil, solvents, and other non-aqueous solutions. Among the many hoses there are hi-vis versions to increase safety, antistatic and anti-spark hoses and certain variants have an FDA approval for use within food and beverage industries.

Technical data

| Temperature range hose | -30 — +60, -30 — +100 °C |

| Max working pressure (bar) | 10 - 16 bar |

| Material hose | EPDM Rubber, PUR |

| Max working pressure (MPa) | 1.0 - 1.6 MPa |

Extensive hose range with high flexibility and durability

The CEJN hose range for compressed air consists of PUR Stream-line hoses and EPDM hoses. The PUR hoses offer a high rate of flow and exceptional resistance to oils, solvents and other non-aqueous solutions. The EPDM rubber hoses are available for antistatic applications. The hoses have excellent recoil ability and are extremely flexible and remain flexible after extensive use.

PUR Stream-line hoses last up to 10 times longer

The PUR Stream-line hoses offer outstanding aging qualities and remain flexible after extensive use. PUR hoses have up to 10 times longer service life than conventional PVC hoses. The CEJN Stream-line quick couplings are the perfect match for our PUR hoses and it will provide long-term reliability without leaks.

Increase safety with hi-vis hoses

Workplace floors can easily be cluttered with cables and hoses lying around as potential tripping hazards. Hi-vis hoses are a safety measure that helps to avoid accidents. Especially when used together with retractable hose reels you have taken a considerable step towards a safer workplace.

Hoses for specific applications

The anti-spark PUR hose is resistant to sparks and scorching for use in welding environments or where cutting equipment is used. There is also the antistatic hose made of EPDM rubber to prevent electrostatic build-up. It is equipped with a protective cover and stands up well to the elements.

Choose the right hose for your requirements

|

|

|

|

|

|

| EPDM Braided Prevents electrostatic build-up |

Straight Braided Durable and wide temperature range |

Straight non-braided Light and flexible |

Spiral non-braided Recoil ability and crimp resistance |

Straight Braided Water For compressed air in damp and wet environments |

|

| Material | EPDM rubber | Ester-based Polyurethane (PUR) | Ester-based Polyurethane (PUR) | Ester-based Polyurethane (PUR) | Ether-based Polyurethane (PUR) |

| Max. working pressure | 12 bar | 16 bar (anti-spark 14 bar) | 10 bar | 10 bar | 10 bar |

| Available as: | |||||

| Hi-Vis | - | ✓ | - | ✓ | - |

| Anti-spark | - | ✓ | - | ✓ | - |

| Antistatic | ✓ | - | - | - | - |

| Stream-line | - | ✓ | ✓ | ✓ | ✓ |

| Available in pre-assembled hose kits | - | ✓ | - | ✓ | - |

Manuals and brochures

Pneumatic Range

Safe, airtight compressed air systems