WEO 350 standard plug-in fittings

Hydraulic push-to-connect fittings

Technical data

| Material | Hardened steel (zinc passivation) |

| Max working pressure (range) | 350 bar (5076 PSI) |

| Min. burst pressure (range) | 1400 bar (20305 PSI), 20305 PSI (1400 bar) |

| Min temperature (C) | -30°C — +100°C (-22°F — +212°F) |

| Material seal | NBR |

The Innovative Problem Solver

The WEO Plug-in will enhance your design in terms of space, time and cost. Avoid leakages and premature hose failures with WEO Plug-in - The Innovative Problem Solver.

Just Plug It In! -The WEO Plug-In system

The WEO fitting is a smart plug-in solution from CEJN offering extensive problem-solving features and cost savings. It is a self-aligning plug-in fitting that enables quick and safe hydraulic hose kit assembly without any tools. The WEO cartridge is used for a fully-integrated, compact design, and our reinforced two-in-one WEO plug-in swivel, for swiveling applications at full working pressure.

5 reasons to integrate WEO in your design:

Time-saving

WEO will save time both during machine manufacturing in the production line and when doing maintenance work like replacing hoses out in the field. WEO takes just a minute to connect, saving valuable time compared to screw couplings.

Compact dimensions

The compact dimensions of the WEO plug-in fittings open new design opportunities, especially when designing with the WEO cartridge and direct porting. WEO has low build dimensions for machine integration and requires only a little space for connection. These features will make it easy to fit WEO into your design.

No leakages

Screw couplings require specific torque for a leak-free and secure connection. Trained personnel are needed for this task to avoid under and over-torquing, resulting in leakage at the final tests. WEO requires none of that. Making a connection can quickly be done by hand, and a screwdriver makes the disconnection easier. With WEO, there is no risk of leaks due to inaccurate torque.

Prevent premature hose failures

When applying torque to screw couplings, embedded tension in the hoses is a common problem. As strained hoses are subject to pressure impulses, hose movement, and even rotation during operation, the lifetime of any such hose is shorter. WEO is self-aligning allowing the hose to find its resting position, minimizing the stress and prolonging its lifetime.

Worker safety and ergonomics

Carrying out time-consuming torquing operations in confined spaces may require awkward postures causing strains. WEO is easy to connect, and it only takes a few seconds.

WEO - Successfully preventing hose failures since 1997

The WEO hydraulic plug-in fittings have been available since 1997. For 25 years, WEO has offered an innovative solution that helps prevent and avoid leaks and extends the hose service life while also facilitating maintenance and hose replacements. These key features are more relevant now than ever. The first 25 years mark the beginning of the journey for WEO.

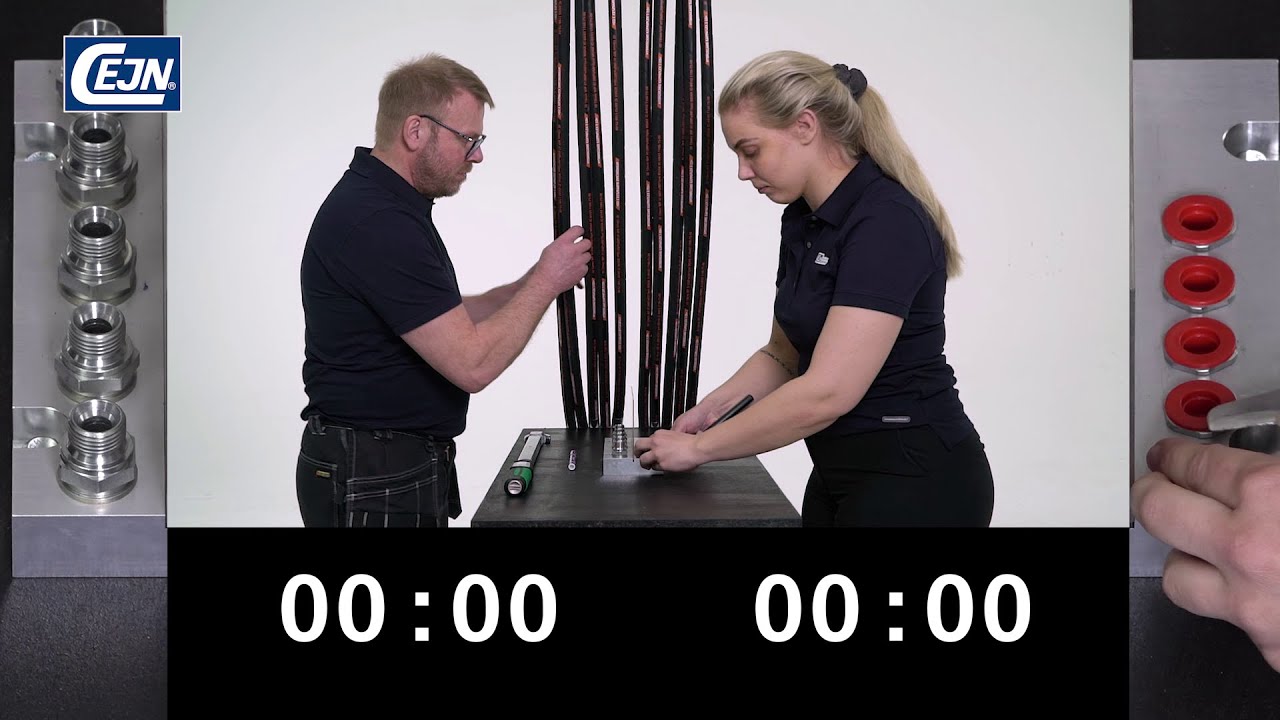

Screw fittings vs WEO Plug-in

WEO is a compact and versatile solution saving time and space. It may even open up new design possibilities compared to conventional screw couplings. The video below is a comparison of the time it takes to install the WEO plug-in compared to screw fittings.

Avoid leaks from under- or over-torquing

Under or over-torquing is a common cause of leaks when using screw fittings. Achieving the correct torque can be difficult and requires trained personnel. With WEO it is just to plug it in and no torquing is required.

Avoid embedded hose tension

When applying torque to screw fittings there is a big risk of embedded tension in the hoses. As strained hoses are subject to pressure impulses, hose movement and even rotation during operation, the lifetime of any such hose is dramatically reduced, resulting in premature failure and leakage. With the self-aligning WEO Plug-In, such hose and leakage problems can easily be avoided.

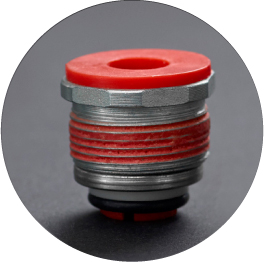

WEO Plug-in Coupling

A compact coupling solution for use with an existing manifold design. The WEO Plug-In coupling offers a multitude of thread or tube connections to replace your current screw fittings. No tools are needed for hose assembly.

Operator safety and quality assurance in focus

In the confined space between chassis and cabin, the operator has to carry out hose connection with a heavy cabin hovering over his head – a very exposed situation. Users of screw-connect fittings always have the challenge of achieving correct torque. Imagine performing this task with no room at all for tools. In many cases, this results in leakage from couplings and embedded tension in hoses that subsequently leads to leakage. With WEO you can work quickly and avoid leakage problems, since all you have to do is plug in.

WEO Plug-in Cartridge

WEO Cartridge is a refined component made for compact system integration. With the WEO cartridge fully integrated into the component design, it will open up new opportunities for a more compact design.

As no adapter is needed, costs are reduced and at the same time, one potential leakage point is eliminated. Reduce the footprint of your final design and enjoy extensive cost savings.

Minimal space requirements enable new design opportunities

With its minimal space requirements, the WEO cartridge allows designers to design new compact hydraulic systems. When incorporating this compact cartridge into your design, you can minimize the footprint of the final design by reducing the space between the ports. This means less material required and reduced costs. Again, since our fittings simply plug in, you don’t have to worry about hand-tool clearance, unlike traditional screw fittings where extra clearance for tools is required when tightening.

WEO Plug-in Swivel

The ideal solution for applications with pressurized moving and rotating hydraulic hoses is the WEO swivel. The WEO Plug-In swivel can rotate 360° while under full working pressure and includes a combined ball and slide bearing, accommodating both hydraulic and torsion forces, resulting in significantly increased service life for your products. WEO Swivel is both a swivel and a plug-in fitting and is as small and flexible as the basic version of WEO Plug-In, giving you a size and weight advantage over commonly-used swivel solutions.

Designed for extreme swiveling applications

An example of an extreme swiveling application is truck-mounted cranes that cause the hoses on the valve blocks to twist and rotate in a way that causes them to wear out. When using the WEO swivel, the hoses can move freely and self-align, with 360-degree rotation under full working pressure. The result is longer hose service life and fewer claims.

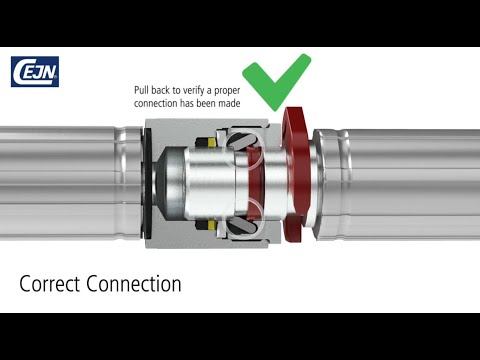

WEO Plug-in Nipple

WEO is designed with an innovative push-to-connect feature that provides quick and quality-assured engagement of the product´s male and female halves. The only time you need a tool is to remove the assembly stop when disconnecting, and this can be done with a screwdriver or similar. Once the assembly stop is removed, you simply push the male nipple all the way in and pull it out from the female component.

The WEO nipple is an open standard. Are you interested in manufacturing your own WEO nipples? Get in contact with us today.

Reduce the overall costs with WEO

On the drawing board

The designer has scope to create more compact and smarter designs with our small and flexible WEO solutions. Designs that will reduce both size and costs.

On the assembly line

If you are working on improving the efficiency of your assembly line, you will first become aware of the time you save. Plus the possibility of making mistakes is eliminated. With a simple plug-in, the connection is achieved without any complicated torque calculations. You often also need to fit a torque wrench into narrow spaces where application of torque is impossible. With WEO, the job is done in no time. It can reduce the time for final testing, as WEO is a Poka-yoke solution.

The machine owner

As an owner of a WEO-equipped machine, you will save both time and money. Instances of twisted hoses that burst due to rotation will be minimised and countless hours will be saved thanks to simplified disassembly.

WEO Nipple – The Global open Standard

By releasing the male part (nipple) as an open standard, CEJN sees a future where WEO is even more accessible around the globe thanks to more manufacturers and shorter distribution chains.

Co-operation is now available from CEJN to customers who wish to receive support in their manufacturing process of nipples. Just a registration and an agreement that the CEJN specifications are followed. It should be easy and accessible to become a WEO nipple manufacturer.

As always when an open standard is created, it is to protect the reputation of WEO and to ensure that the end user gets interchangeability, highest quality, performance and safety. The CEJN service will consist of specifications such as drawings and process parameters to reach specified performance and quality level. If changes are made on those parameters, CEJN will update the registered manufacturers.

Manuals and brochures

Clean and Leak-Free Hydraulic Systems

WEO Plug-In - The Innovative Problem Solver

WEO Plug-In