Check the pressure in your hydraulic system

Check the pressure in your hydraulic system on the fly with our range of pressure testing nipples that fits the world’s most common test-point system.

-

Leakage free even with low viscosity fluids

-

Extra long-lasting with zinc-nickel treatment

-

Excellent impulse test performance

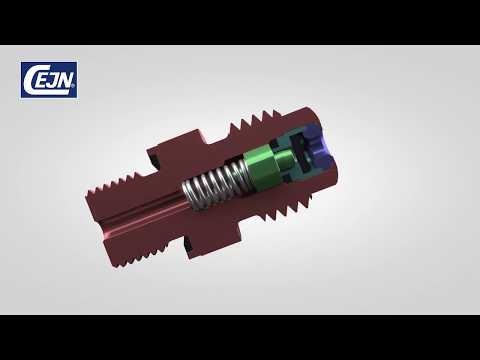

Screw-to-connect pressure testing

The pressure testing nipples are designed to work with most fittings available (ISO 15171-2) and offer a leakage-free solution, even when using low viscosity fluids. Our test nipples are made of Zinc-nickel plated special steel. That makes them less prone to rusting than conventional products.

With a working pressure of up to 9137 PSI (630 bar), it is ideal for pressure check, lubrication and air bleeding in hydraulic systems. It can also be used in micro hydraulics.

Manuals and brochures

Pressure Testing Nipples / Series 359