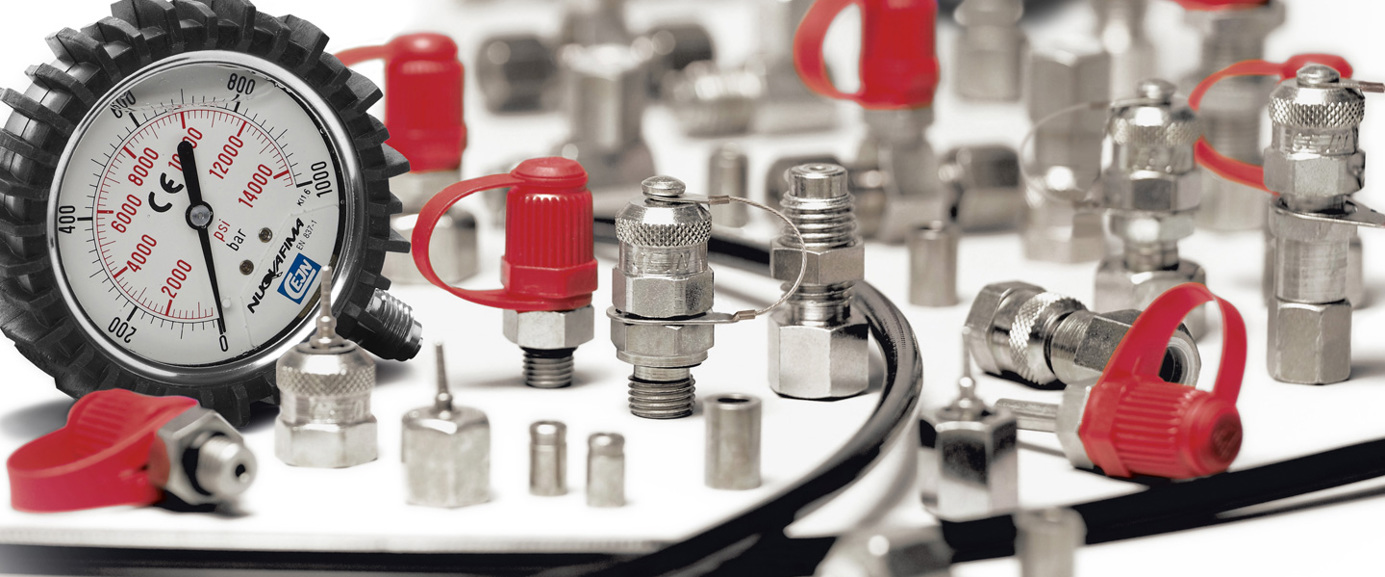

Check the pressure in your hydraulic system

Check the pressure in your hydraulic system on the fly with our range of pressure testing nipples that fits the world’s most common test-point system.

- Leakage free even with low viscosity fluids

- Extra long-lasting with zinc-nickel treatment

- Excellent impulse test performance

The pressure testing nipples are designed to work with most fittings available (ISO 15171-2) and offers a leakage-free solution, even when using low viscosity fluids. Our test nipples are made of Zinc-nickel-plated special steel. That makes them less prone to rusting than conventional products.

With a working pressure of up to 630 bar, it is ideal for pressure check, lubrication and air bleeding in hydraulic systems. It can also be used in microhydraulics.

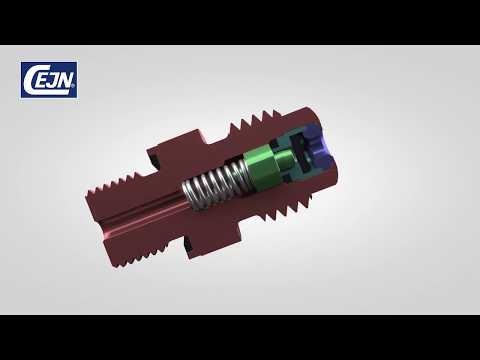

The new poppet-style test points will be introduced gradually, replacing the ball-valve test points. It has shown excellent results in impulse tests, exceeding long-term cycle tests.

Related Stories

Step-by-step guide: How to change the seal on CEJN TLX coupling

Using products that last is a sustainable choice for both the wallet and the planet. Rather than disposing of a product once it reaches the end of its service life, we offer a wide range of spare...

Step-by-step guide: How to install CEJN TLX on hydraulic attachments

In heavy-duty applications, the failure of quick-connect couplings often comes from high surge flows. These surges can lead to seal failures and machine damage, resulting in costly leakages and machine downtime. CEJN TLX is a super-duty coupling solution specifically designed to withstand the...

WEO hydraulic plug-in fittings now available in 5/8”

WEO hydraulic plug-in fittings are known for the versatility and space and time-saving features that also help prevent leakages and premature hose failures. To make WEO available for even more...