Step-by-step guide: How to change the seal on CEJN TLX coupling

Using products that last is a sustainable choice for both the wallet and the planet. Rather than disposing of a product once it reaches the end of its service life, we offer a wide range of spare parts that will make the product run for many more service hours. In this guide, we provide instructions on how to replace the seal on the CEJN TLX, ensuring continued performance and longevity in the toughest construction and demolition applications.

A long service life with many operational hours is the core of an efficient workflow. Changing spare parts instead of replacing the complete coupling is both sustainable and cost-effective. Watch the instruction video or follow the step-by-step guide underneath on how to easily change the seal on CEJN TLX. These tools are required: a cable tie or similar, a tool to push down the valve sleeve, and an O-ring hook tool.

- Turn off the oil flow before unscrewing the coupling.

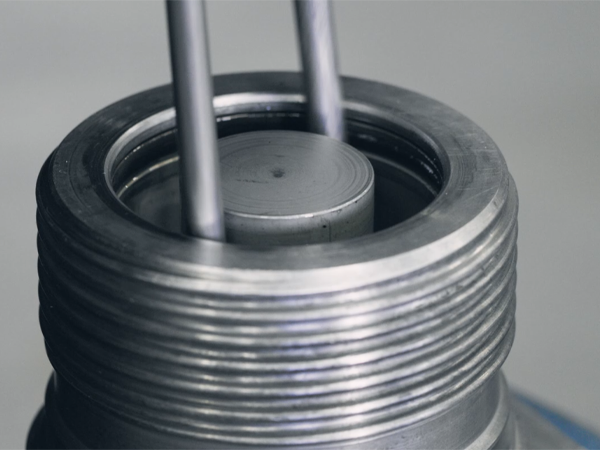

2. Push down the valve sleeve and insert a cable tie to keep it in place

3. Use an O-ring tool to remove the O-ring- and backup ring.

4. Insert the new O-ring.

5. Insert the new backup ring and make sure it is oriented correctly

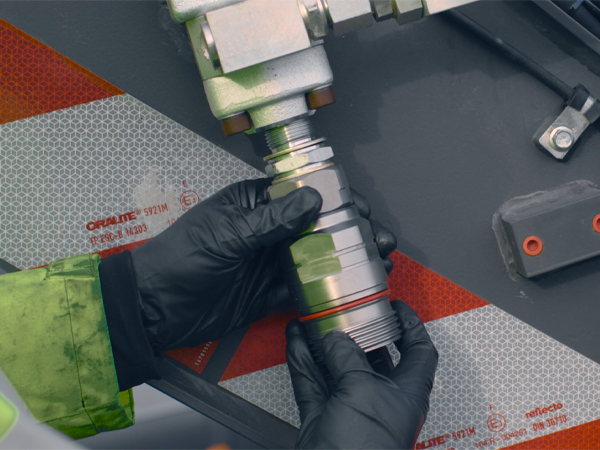

6. Make sure to be gentle to not damage the seals when assembling.

7. Push down the valve sleeve and remove the cable tie.

8. Connect the TLX coupling to the machine again.

9. Turn on the oil flow.

This is CEJN TLX

CEJN TLX is a hydraulic flat-face twist lock coupling made for the toughest construction and demolition applications. This super-duty quick connect coupling is designed to work with the highest surge flows and the toughest pressure impulses.

Read more here

Related Stories

Step-by-step guide: How to install CEJN TLX on hydraulic attachments

In heavy-duty applications, the failure of quick-connect couplings often comes from high surge flows. These surges can lead to seal failures and machine damage, resulting in costly leakages and machine downtime. CEJN TLX is a super-duty coupling solution specifically designed to withstand the...

WEO hydraulic plug-in fittings now available in 5/8”

WEO hydraulic plug-in fittings are known for the versatility and space and time-saving features that also help prevent leakages and premature hose failures. To make WEO available for even more...

Increased performance and no more oil leaks for Reinhard Recycling after installing CEJN TLX

Reinhard Recycling had a problem with oil leaks when disconnecting their couplings from the hydraulic attachments. They were recommended CEJN TLX, a super-duty coupling solution designed to work with...