“WEO provides a problem-free solution”

A problem-free solution with a good swivel function was one of the things on the wish list of ICAR BAZZOLI, an Italian crane manufacturer. Instead the company suffered from leaking and low-quality connections on the hydro control valves. CEJN presented the WEO swivel to ICAR BAZZOLI, who immediately saw the potential and made the switch. This has resulted in extended hose life and leakage being reduced to a minimum.

Crane manufacturer ICAR BAZZOLI has its headquarters located in the municipality of Guidizzolo outside Mantova, northern Italy. The company has a long history and started out producing agricultural loaders, but today specialises in manufacturing forestry and recycling cranes for tractors, trucks and trailers. All the cranes are assembled in Guidizzolo, but components come from a number of specialised subsidiaries around the country, all part of the ICAR BAZZOLI group.

Alessandro Bazzoli is the third generation in this family-owned business and he is in charge of the technical and commercial aspects. He works side by side with his father Enzo Bazzoli, the President and his brother Federico. The company was founded in 1952, by Guido Bazzoli.

Looking for a leak-free solution. ICAR BAZZOLI originally had a swivel-type connection for their hydro control valves, a solution that remained from their time within the agricultural sector. However, product quality was inadequate and father and son were actively looking for a better solution. “Our machines are in heavy use eight hours a day and both hose and couplings are subjected to heavy wear and tear, resulting in leakage,” explains Alessandro. They started to investigate the connection market, but the result was unfortunately always the same - leakage.

A couple of years ago ICAR BAZZOLI was exhibiting at a fair and encountered CEJN and the WEO swivel. “We became very curious about this solution and we also saw that some of our competitors were using it as well,” explains Alessandro, and continues: “We tried it out, with good results, and slowly we started to switch to WEO at our production facility”.

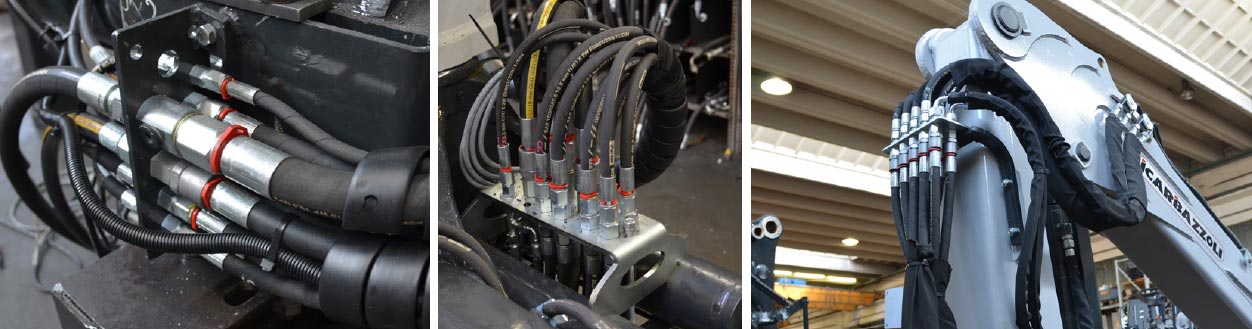

WEO solves leakage problem. ICAR BAZZOLI has now been using WEO swivels for three years. In 95% of cases the WEO is installed in the hydro control valves in the bottom section of the crane. However, in certain cases it is located in the upper crane axis. In both instances, the WEO handles the swivel function without leakage.

”CEJN ’s WEO has improved the quality of our machines”

ICAR BAZZOLI purchases nipples from CEJN and sells them to a partner who carries out the crimping process and provides them with ready-to-use hose kits. This solution has worked out very well with no problems.Alessandro says: “With WEO we have a problem-free solution with no claims, just what we’ve been looking for”. In addition to the quality of the products, ICAR BAZZOLI is pleased with the quick response and service from CEJN. “Ultimately, CEJN ’s WEO has improved the quality of our machines,” concludes Alessandro.

Related Stories

Step-by-step guide: How to change the seal on CEJN TLX coupling

Using products that last is a sustainable choice for both the wallet and the planet. Rather than disposing of a product once it reaches the end of its service life, we offer a wide range of spare...

Step-by-step guide: How to install CEJN TLX on hydraulic attachments

In heavy-duty applications, the failure of quick-connect couplings often comes from high surge flows. These surges can lead to seal failures and machine damage, resulting in costly leakages and machine downtime. CEJN TLX is a super-duty coupling solution specifically designed to withstand the...

WEO hydraulic plug-in fittings now available in 5/8”

WEO hydraulic plug-in fittings are known for the versatility and space and time-saving features that also help prevent leakages and premature hose failures. To make WEO available for even more...