Prevent hose damage when working with ultra high-pressure hydraulics

We know that the definition of ultra high-pressure hydraulics sometimes can be a bit confusing depending on who you talk to and in which context. At CEJN, we define ultra high-pressure when the pressure is 700 bar or more. In other words, extreme pressure that requires extreme safety.

Working with ultra high-pressure hydraulics is a serious task and needs to be handled with respect. One out of 600 hand traumatisms is caused by high-pressure injuries, according to a paper from the medical journal Hippokratia. Some are minor, resulting in bruising, while others, unfortunately, can result in much more severe injuries. Many of these accidents could have been avoided with the right knowledge, precautions, and products.

At CEJN, we believe that an effective way of maintaining workplace safety when working with ultra high-pressure hoses is to make workers aware of the potential hazards. Despite the obvious dangers, it can and should be perfectly safe to use.

In this article, we will focus on ultra high-pressure hoses and how to prevent hose damage before something happens.

Be aware of the potential hazards

Hose assemblies may fail abruptly and unexpectedly due to a variety of reasons. Hydraulic oil shooting out at high pressure and/or at high speed can cause severe oil injection injury and serious damage to machinery, as well as polluting the environment. Therefore, we have put together a guide and a checklist on what to look for in order to prevent hose damage.

- Never use a hose with cuts or wire showing through the outer cover.

- Never use a hose with bubbles, blisters, or kinks.

- Do not exceed the bend radius and pressure rating for each hose.

- Anti-kink protection is not a carry handle.

- Do not run over or crush the hose with a vehicle.

- Avoid using a hose with corroded or leaking end connections.

- Avoid using an adulterated medium or a medium containing Sulphur compound.

- Do not bend the hose over scaffolding or pull heavy equipment with it.

- Do not let the hose support its own weight off towers or buildings.

- Do not expect water jetting or hydraulic hose to last forever.

- Do not change or repair a hose without instructions from the manufacturer.

- Never disconnect a hose under pressure.

- Never fix a hose at the sleeves.

Moreover, if injected with high-pressure fluid, get to the nearest emergency unit immediately. Once at the hospital, tell the emergency staff that you suspect to have gotten a fluid injection. Don’t forget to bring the safety data sheet for which fluid you have been injured with as it contains important information for the hospital staff. They will then be able to give you the right treatment.

Risks with poorly crimped hoses

Poorly performed ultra high-pressure crimping processes are a threat to people working in any business demanding ultra high-pressure hose-sets. Hose crimping requires a high degree of professional knowledge. It is a meticulous working process and is not the same as crimping a hydraulic hose for low or medium pressures. Hose failure due to incorrect crimping can result in severe injuries as an outcome.

At CEJN, each hose kit is pressure tested before delivery to ensure safe operation and optimum performance. After delivery, it’s important that the hose assemblies are being pressure tested and inspected on a regular basis to make sure they are not worn out or damaged.

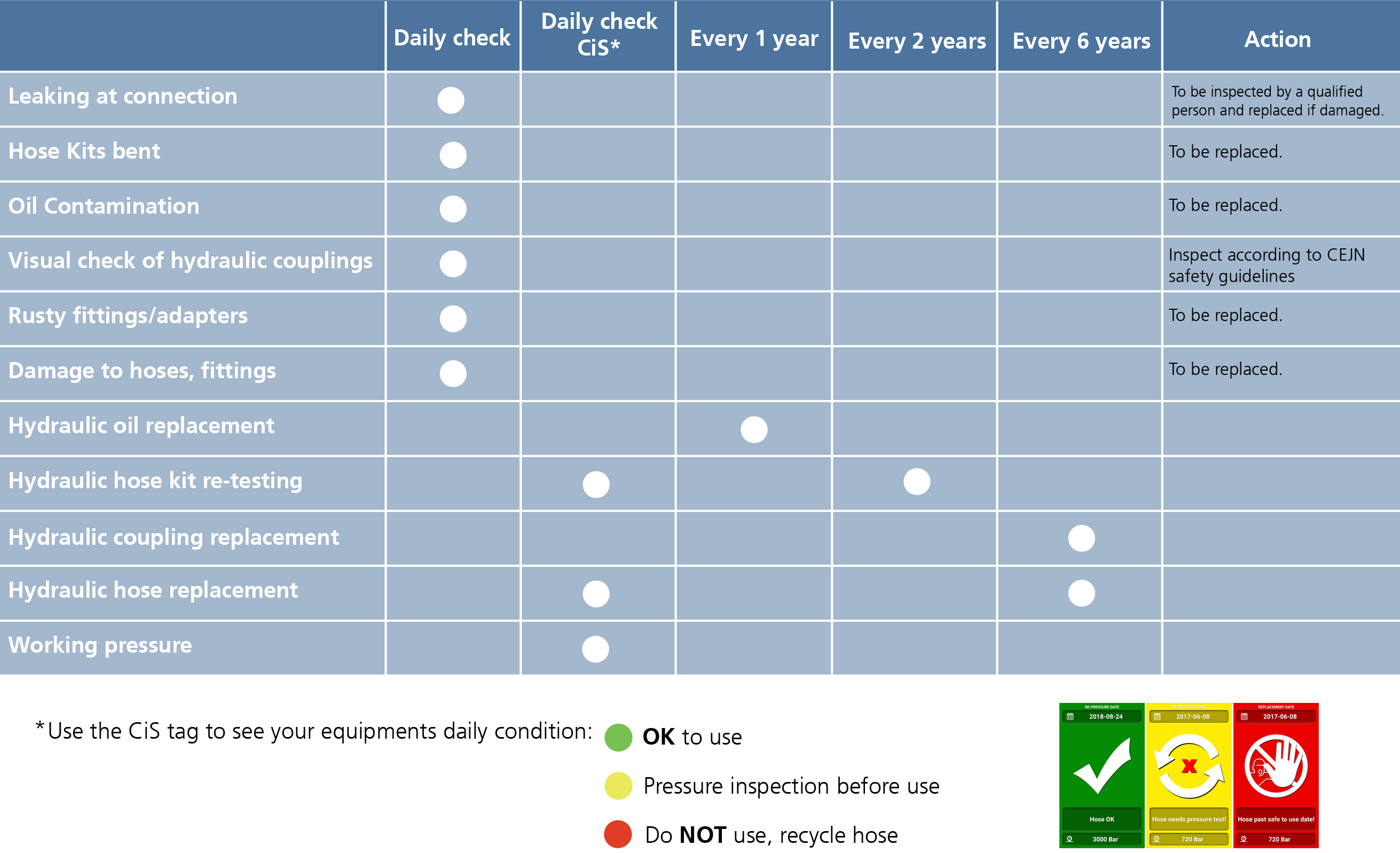

If you are unsure when to check your hose kits, use the below control card for guidance:

Related Stories

Introducing T-Coax – The hassle-free torque wrench connector

The market is rapidly shifting towards a more convenient, clean, and hassle-free way of connecting hydraulic torque wrenches. The T-Coax hydraulic connection system is designed for an easier, cleaner...

CEJN provides Bemco Hydraulics with safe and reliable ultra-high-pressure hydraulic equipment for re-railing operations

In an efficient re-railing operation, every detail in the process counts towards minimizing the degree of stranded traffic. Bemco Hydraulics, an Indian manufacturer and supplier of hydraulic re...

Introducing high-pressure hose reels with stainless steel swivel for hassle-free and flexible operations in the field

The high-pressure hydraulic hose reels with a stainless steel swivel are assembled and ready to use for quick deployment, mobilization and demobilization of pressure lines. The hose reels are...