ultraFLOW STC couplings

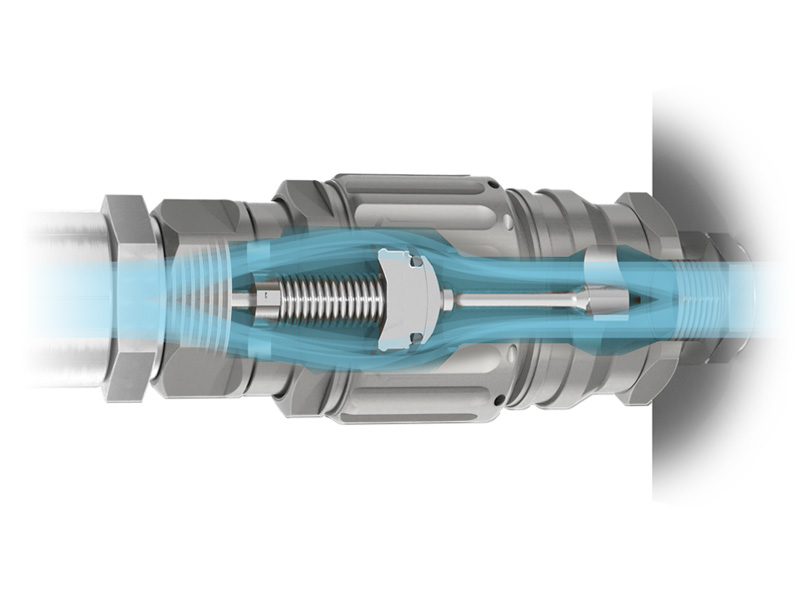

ultraFLOW STC is a screw-to-connect version of the ultraFLOW series of quick couplings specifically designed for liquid cooling of electronics. With its larger inner diameter, it is ideal for the cooling distribution unit (CDU) in the liquid cooling system. High flow and low pressure drop are significant features of the ultraFLOW family of quick couplings, enabling new design opportunities to save energy and lower investment costs.

Technical data

| Nominal flow diameter (mm) | 32 mm |

| Max working pressure (bar) | 10 bar |

Screw-to-connect couplings for liquid cooling distribution units (CDUs)

The ultraFLOW STC screw-to-connect couplings offer large-diameter versions of the spill-free ultraFLOW series. As the larger diameter and higher flow rate increase the required connection force, the STC version is of screw-to-connect type to overcome this and make the connection effortless. The ultraFLOW STC has the same great features as other versions in the ultraFLOW family, a spill-free coupling that is highly durable and with extremely low pressure drop. Combining our long experience in spill-free couplings for hydraulics with the emerging technologies within liquid cooling has led to a highly efficient quick coupling based on a proven design.

The ultraFLOW STC is suitable for the inlets and outlets of cooling distribution units (CDU) in data centers. Other applications requiring increased flow rate may include wind turbines, traction power converters, energy storage systems, etc.

Low pressure drop saves energy and reduces investment costs

Compared to other couplings of the same size, the flow capacity and pressure drop performance of the ultraFLOW STC outperforms the competition. When looking at the overall performance of the total liquid cooling system, the pressure drop performance is of high importance. The pressure drop from each component adds up. The positive effects of the difference between a good and a slightly better component are increasing for each component in the system. It may as well be the deciding factor influencing the total design, even allowing to downsize the pump to lower the investment cost and reduce energy consumption.

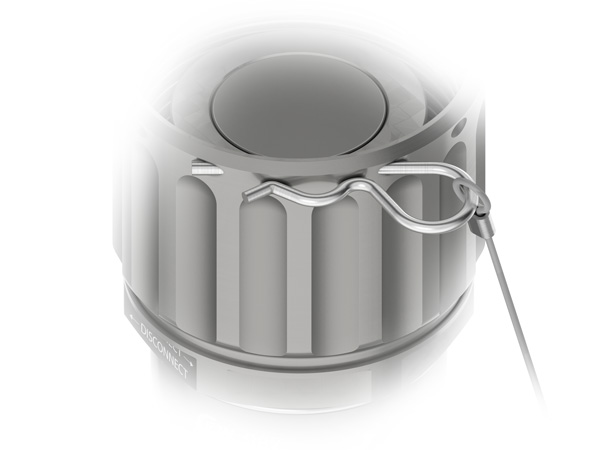

Safety alert ring

The connection is not completed as long as the red alert ring is visible. Once fully covered, it is a clear indicator of a safe connection.

Optional safety pin

An optional safety pin can be added for an extra level of safety for the connection. The safety pin will practically eliminate any risk of accidental disconnections even when exposed to heavy vibrations.

Optional color coding

Color-coded rings in blue and red are available to indicate in or outgoing lines.

Easier maintenance with spill-free quick couplings

Spill-free quick couplings facilitate maintenance when there is no need to drain the system for maintenance operations. Sections or parts of the system can easily be disconnected and removed for maintenance while maintaining circuit integrity and avoiding spilling of fluid in an environment with sensitive electronic equipment. Spill-free quick couplings are also preferred considering the operator safety and environmental aspects when using engineered fluids, ethylene glycol mixtures, or other toxic and possibly hazardous liquids. Emptying/refilling operations that require the trapped air to be evacuated are time-consuming. By using spill-free couplings, these operations are not even necessary.

Quick Connect Couplings:

A Critical Component in Liquid Thermal Management Solutions