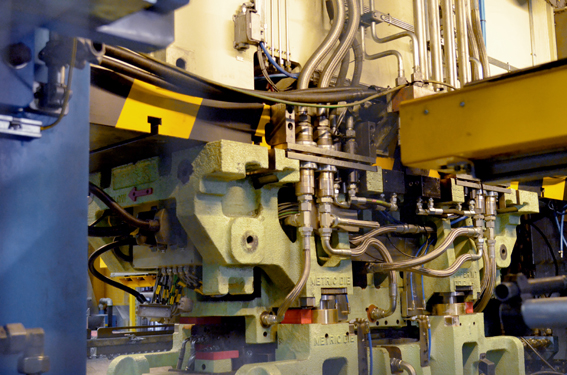

Multiple connections and Poka Yoke

The customized press plate from CEJN is designed to facilitate the connecting process when linking the press and tool together at a press hardening facility. Prior to the introduction of the multi-plate solution, the operator had to manually connect a series of single couplings, which was time-consuming, hard and very dirty work. The new multi-plate docks automatically and enables five different connections to be made, including hydraulics, cooling water and compressed air, saving both time and money. It also eliminates the possibility of cross-connection. The plate has screw holes, meaning it can be mounted “floating”. This floating design corrects any misalignment and ensures faultless connection, in quality management terms called Poka Yoke.

Material

As there is no imminent risk of corrosion, the plate is made from the same material as the tools on which it will be mounted – steel. The quick disconnect couplings used on this particular plate are CEJN’s reliable auto-couplings for liquid and hydraulics. The guide pins that steer the plate into position are self-lubricating and thus maintenance-free, which eliminates service time.

Durability and delivery

This product has also proved to be extremely durable, exceeding the service life of the customer’s own tools, which is around 7 years. The delivery time for this application from request to delivery was three months.