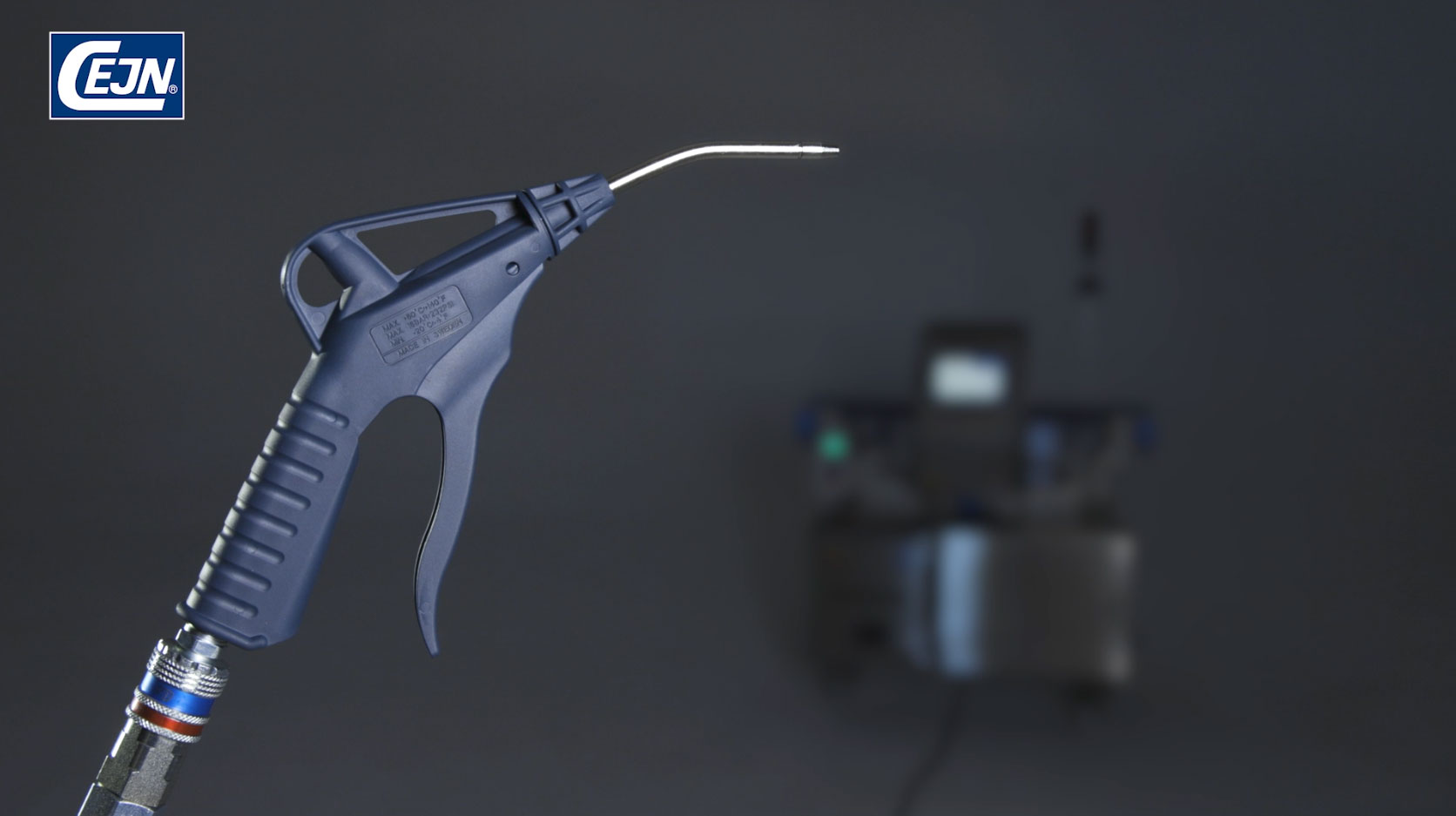

Introducing the 208 Detect blow gun - developed for improved food safety within the food and beverage industry

Within the food and beverage sector, the primary focus remains on upholding the most rigorous standards of food safety. To enhance the safety of the production process, CEJN launches a cutting-edge product: the 208 Detect blow gun, specifically designed and manufactured to improve food safety.

We extend our blow gun range with a new, groundbreaking innovation: the 208 Detect blow gun, made of detectable plastic to improve food safety in the food and beverage production process. It is the first metal and X-ray detectable blow gun to be introduced on the global market, reducing the risks of accidental contamination, product rejections, expensive re-calls and waste.

Food safety systems such as HACCP, IFS and BRC have identified foreign body (undesirable solid object found in food) contamination as one of the main risks in the production process, whereas metals and plastic are two of the most common physical contaminants found in food. As the food grade plastic of the 208 Detect blow gun enables plastic pieces as small as 2x2 mm* to be detected in metal detectors and X-rays, it can be implemented as part of HACCP, IFS and BRC procedures.

Except for being detectable, the 208 Detect blow gun has the same great features as the regular 208 blow gun: high flow, lightweight and ergonomic, robust design and smooth flow control, to name some.

Experience all the features and the difference between using a detectable blow gun vs. a non-detectable blow gun by watching this demonstration movie.

*The size of the plastic pieces that can be detected depends on the metal detector itself and how the detector is calibrated.

Related Stories

Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

How much do leakages in the compressed air system actually cost? For the industrial facilities at the Hägglund area owned by NP3 real estate, too much it turned out. After measuring and localizing the...

Compressed air optimisation: 5 common leak sources in compressed air systems

Compressed air systems offer a versatile and efficient power source within many industries. High reliability and a favourable cost/performance ratio have kept the compressed air solutions a top...

Introducing the 209 air and fluid guns – designed for workplace ergonomics

CEJN is thrilled to unveil that we now extend our product line for air and fluid guns with a new addition: the 209 air and fluid guns, designed for workplace ergonomics...