Improve your forklift design and production efficiency with WEO Plug-In

Enhance your forklift design in terms of space, time and costs with WEO plug-in – a smart fitting solution that enables flexibility, compact system integrations and quick connection and disconnection without any leakage in confined spaces.

This is how WEO plug-in can help to improve cost and production efficiency within the forklift industry:

For the engineer/designer - integrated and compact design with WEO cartridge

For the production manager - safe and quick assembly with WEO plug-in

For the supply chain manager - overall cost reduction giving improved performance and profitability

For the hose kit supplier - WEO plug-in nipple global open standard

Just plug it in!

As simple as it sounds. The WEO fitting is a smart plug-in solution, offering extensive problem-solving features and cost savings. This self-aligning plug-in fitting enables quick and safe hydraulic hose kit assembly without needing any tools.

For the engineer - compact system integration with WEO Cartridge

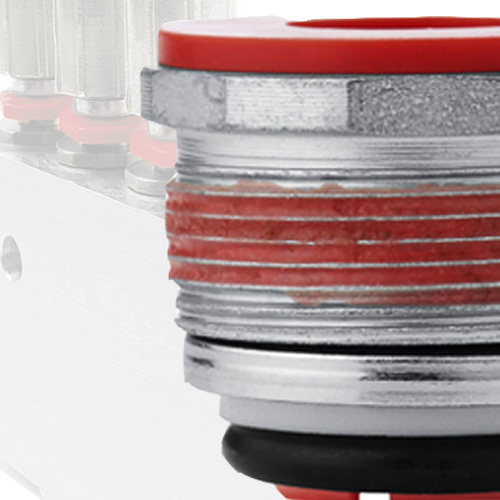

Discover new design possibilities with the core of our design: the WEO Cartridge, a fully integrated slim size quick coupling, designed to fit the most compact and confined spaces. Also, as no adapter is needed, costs are reduced and at the same time, potential leaks are eliminated.

COMPACT DESIGN

By integrating the WEO Cartridge into your forklift design, you can minimize the footprint thanks to its compact size. In addition, no tools are needed during hose assembly making it ideal in confined spaces.

NO LEAKAGE

With WEO, no torque process is required. Leakage problems due to over or under torquing of screw fittings are thereby prevented as all you have to do is plug-in.

EXTENDED HOSE LIFE

Hose manufacturers state that twisting a hose just by 5 degrees can reduce the hose lifetime by 70%. With our self-aligning WEO, hoses last longer as there is no embedded tension to wear them out.

"WEO is a safe, quality-assured and durable product"

- Fredrik Grahn, Workshop Technician at FMC

For the production manager - quick and safe assembly with WEO Plug-In

As a production manager or likewise, you know that safety is the major focus. In the confined space between the forklift chassis and cabin, the operator has to carry out the hose connection with a heavy cabin hovering over his head, in other words, a very exposed situation.

Users of screw-connect fittings always have the challenge of achieving correct torque. Imagine performing this task with no room at all for any tools. In many cases, this results in leakage. With WEO plug-in fittings you can work safely, quickly, and avoid leakage problems since all you have to do is plug-in.

HEALTH & SAFETY

With WEO plug-in, there are no torque processes in confined spaces that could cause personnel injury. Exposure is minimized thanks to a quick assembly process. Also, by just plugging in, awkward postures that can cause strains are avoided resulting in better ergonomics.

TIME-SAVING

In fact that all you have to do is plug-in means a considerable reduction in assembly time - making the work more efficient.

NO RE-WORK

With no risk for under and/or over-torque, there will be less re-work due to human error. Saving both time and money.

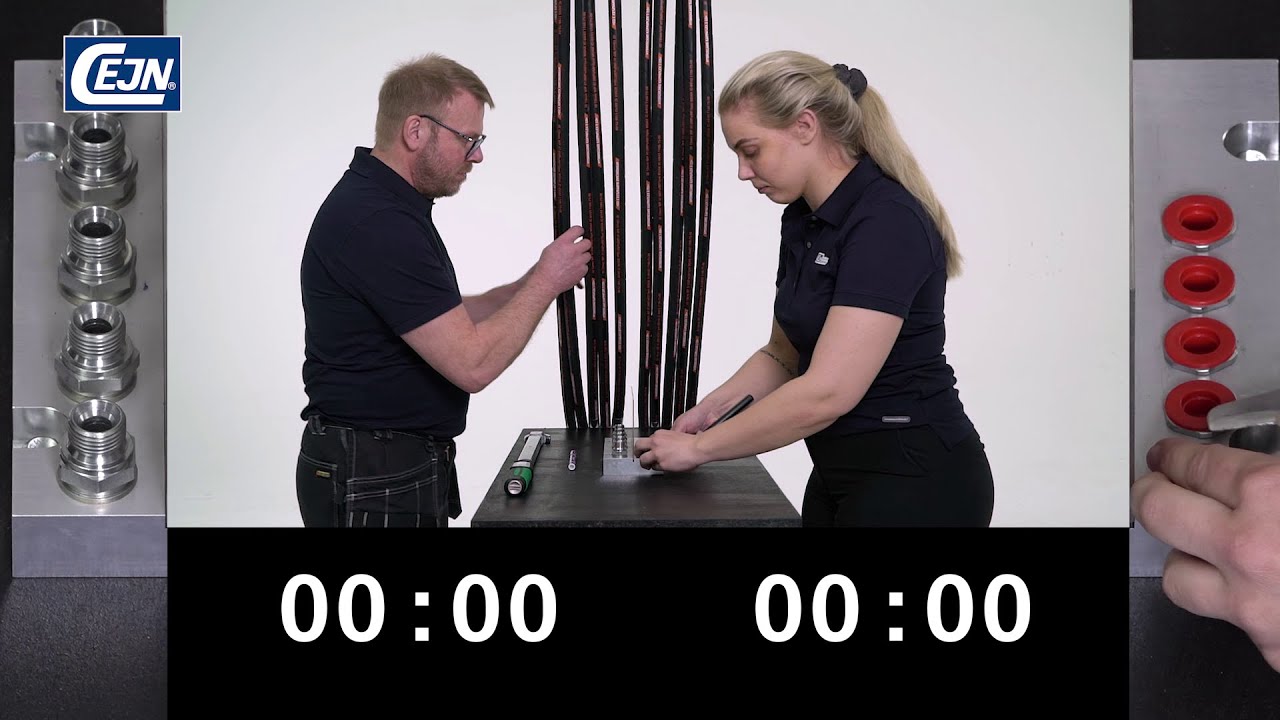

WEO plug-in vs. screw couplings

Experience the difference in time, space and design possibilities by watching this comparison movie with WEO plug-in vs. Screw couplings.

For the supply chain manager - total cost efficiency with WEO Plug-In

Do you want to reduce overall cost, improve product performance and increase your profitability? If using WEO Plug-In, you have many benefits that together will give this effect. Reducing assembly time in a safe way, avoiding re-work due to leakage at final testing, avoid warranty claims due to leakage or premature hose failures will together give the reduced overall cost and increase your profitability.

For the hose kit supplier - quick connections with WEO nipple

WEO is designed with an innovative push-to-connect feature that provides quick and quality-assured engagement of the product´s male and female halves. The only time you need a tool is to remove the assembly stop when disconnecting, and this can be done with a screwdriver or similar. Once the assembly stop is removed, you simply push the male nipple all the way in and pull it out from the female component.

By releasing the male part (nipple) as an open standard, the CEJN WEO is even more accessible around the globe thanks to more manufactures and shorter distribution chains. By signing a "Specification conformance agreement" all specifications to locally produce the male nipple will be supplied by CEJN: Plug in to WEO - The global open standard | CEJN

Order a free sample of the WEO Plug-in

Sign up to order a free WEO sample. The offer is valid as long as there are samples available in stock.