Clearing OSHA Requirements with Low-Noise Blowguns

Our client is from the Oil & Gas industrial area and operates a large manufacturing facility in Singapore. We meet with their HSE Coordinator who takes us through the facility cheerfully, talking freely on how they take on the lofty challenge of safety in the workplace. During the visit, we meet with a few, of the nearly 200 employees using CEJN products to know more about the application and how CEJN blowguns contribute to a safer workplace.

It all started with reel experience

The shop floor looks immaculate and equipment well in order, hinting at the high levels of effectiveness they devote themselves to. Seeing pops of blue here and there in the form of CEJN hose reels, our guide points out that they bought 120 hose and cable reels 3-4 years ago, to declutter the floor space, preventing tripping.

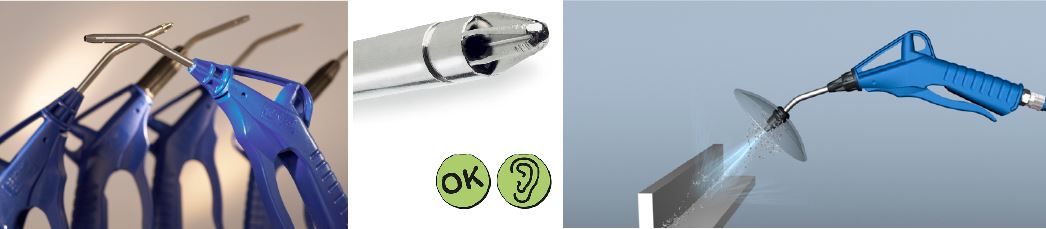

This client also approached CEJN Products Far East about half a year ago, after googling for low-noise blowguns that meet the OSHA criteria (Safety and Health at Work) of a pressure below 2 bars (30 psi) when dead ended. The production floor had 130+ blowguns that had to be replaced to prevent danger to employees in potential situations of dead ending.

The aim of this Directive is to introduce measures to encourage improvements in the safety and health of workers at work.

- OSHA directive

Greater safety for staff

To suit the application and keep colleagues safe, management decided that the CEJN Series 208 blowgun had to be customized with an extension tube and chip-shield. There are several stations equipped with the low-noise blowguns, and they are mainly used to clean burrs, excess oil or coolant off components. Each station has different requirements and use different lengths of the extension tube to accomplish their tasks. Chip shields were also installed to protect workers from flying debris, as further protection to safety goggles that are strictly mandatory on the shop floor.

Blowgun use is integral at work

Stopping by a series of CNC machines, an employee is busy at his station. Speaking to us at intervals between procedures that he firmly knows by heart, he tells of how often he uses the low-noise blowguns.

Excess coolant has to be removed by the blowgun between every step, to a frequency that even the operator can’t estimate how many times he reaches for the blowgun in a day. And when asked what the overall experience of the blowgun is, he says “It works perfectly and it is much quieter than the last one we had”.

Efficiency maintained at work

We then watched a staff with 3 years of experience tackle the many pallets of parts lined up for him. He smiles as he mentions that the high flow of the low-noise blowguns help him keep at his work efficiently. Some parts that he cleans are pipes more than a meter long, and the high flow is crucial for him to do a thorough job. Before we left him to his responsibilities, we asked if any improvements can be done and he says that a longer tube would not hurt.

Safety as a continuous process

“I’m always open to more safety improvements,” the HSE Coordinator says, in discussion of other possibilities for a safer environment, expressing the company’s open attitude towards change for increased safety. Wrapping up the tour, we leave the air-conditioned workshop. We shook hands, glad to have experienced the educational tour and stepped back out under the warm blazing sun.

Related Stories

Industry facility saves over €40,000 a year after optimizing their compressed air system with CEJN products

How much do leakages in the compressed air system actually cost? For the industrial facilities at the Hägglund area owned by NP3 real estate, too much it turned out. After measuring and localizing the...

Introducing the 208 Detect blow gun - developed for improved food safety within the food and beverage industry

Within the food and beverage sector, the primary focus remains on upholding the most rigorous standards of food safety. To enhance the safety of the production process, CEJN launches a cutting-edge...

Compressed air optimisation: 5 common leak sources in compressed air systems

Compressed air systems offer a versatile and efficient power source within many industries. High reliability and a favourable cost/performance ratio have kept the compressed air solutions a top...